electronics-journal.com

21

'21

Written on Modified on

Negative Stiffness Vibration Isolation Supports New Compact, Portable and User-Friendly AFM

Since the release of the first commercial atomic force microscope (AFM) about 30 years ago, technology advances have steadily been implemented to improve their performance. Now, the most recent advance in ambient-temperature AFMs is making them more compact, portable and user-friendly, which is enabled by Negative-Stiffness vibration isolation.

The atomic force microscope (AFM) has become one of the foremost tools for imaging and measuring materials and cells on the nanoscale. Revealing sample details at the atomic level, with resolution on the order of fractions of a nanometer, the AFM is instrumental for imaging an array of applications, such as defining surface characterizations, lithography, data storage, and manipulation of atoms and nano-sized structures on a variety of surfaces.

The AFM utilizes a sharp tip (probe) – with a radius of curvature on the order of a few nanometers – attached to the end of a tiny cantilever used to scan across a sample surface to image its topography and material properties. When the tip is brought into proximity of a sample surface, forces between the tip and the surface lead to a deflection of the cantilever. This deflection is recorded using, typically, a laser beam that is reflected from the top surface of the cantilever to a photo-sensitive detector. The resultant change of position of the cantilever/probe/tip permits characteristics such as mechanical, electrostatic, magnetic, chemical and other forces to be precisely measured by the AFM. These characteristics are displayed in a three-dimensional surface profile of the sample (in the X, Y and Z axes), an advantage that the AFM can provide compared to other microscopy techniques.

Although AFM technology has advanced considerably, its benefits have not always been easily accessible for researchers requiring AFM adaptability, portability. Nor have AFMs been adequately accessible in nanotechnology student laboratories, because of lack of student skill in their operation, and budget limitations on the number of AFMs at their disposal.

A More Portable, More User-Friendly AFM

These inhibitions have now been mitigated by a relatively new compact, portable and user-friendly ambient-temperature AFM. Developed by NanoMagnetics Instruments, a leading manufacturer of scanning probe microscopes for low-temperature applications, the ezAFM+ atomic force microscope is a benchtop instrument designed for short learning times, quick setup, and ease of transport.

“This AFM has excellent system performance, comparable with traditional AFMs,” said Kent Schuyler, North American Manager for NanoMagnetics Instruments/NMI. “The core of what NMI designs and builds are scanning probe microscopes/SPMs for low-temperature applications. We have engineered this legacy technology into an easier to use ambient-temperature, more portable AFM than what was currently available on the market. This new instrument is the ezAFM+.”

The ezAFM+ operates in full mechanical and electrical SPM modes such as tapping, Kelvin probe and DMT. STM is also a plug-and-play option that requires highly effective, mechanical isolation. This new AFM has exceptional scan range on the order of 150um in X&Y, and 100um Z that is somewhat adaptable to the application. The scanner utilizes voice coil motors (VCM) rather than more traditional piezo-based motors. Voice coils enable exceptional range while sustaining tip-limited resolution. Well integrated optics provide better than 2 µm resolution and extremely functional electronic focus.

Negative-Stiffness Vibration Isolation

AFM systems are extremely susceptible to vibrations from the environment. The need for more precise vibration isolation with atomic force microscopy is becoming more critical as resolutions continue to bridge from micro to nano. When measuring a very few angstroms or nanometers of displacement, an absolutely stable surface must be established for the instrument. Any vibration coupled into the mechanical structure of the instrument will cause vertical and/or horizontal noise and bring about a reduction in the ability to measure with the highest resolution. The vertical axis is the most sensitive for AFMs, but AFMs are also quite sensitive to vibrations in the X and Y axes.

“During development of the ezAFM+ we considered a number of options for vibration isolation,” continued Schuyler. “Weighted masses hung from bungee cords, air tables, and active vibration. We have primarily decided on Negative-Stiffness vibration isolation. Consequently, this portable new AFM comes equipped with a state-of-the-art vibration isolation platform which is also portable and easy to operate.”

Developed and patented by Minus K Technology, Negative-Stiffness isolators provide a unique capability to the field of AFM research. They employ a completely passive, mechanical concept in vibration isolation, with no air or electricity required. There are no electronics, motors or pumps. They operate completely in a passive mechanical mode, while achieving a high level of isolation in multiple directions.

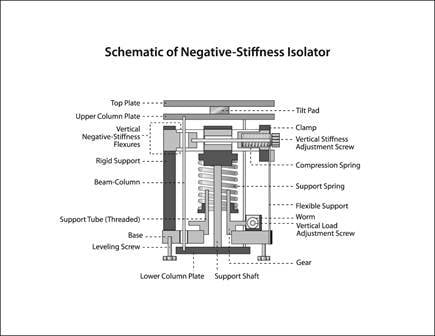

Negative-Stiffness vibration isolator.

“In Negative-Stiffness vibration isolation, vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a Negative-Stiffness mechanism,” explained Dr. David Platus, inventor of Negative-Stiffness isolators, and President and Founder of Minus K Technology. “The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. A beam-column behaves as a spring combined with a Negative-Stiffness mechanism. The result is a compact passive isolator capable of very low vertical and horizontal natural frequencies and very high internal structural frequencies.”

Vibration Transmissibility

“Negative-Stiffness isolators deliver very high performance, as measured by a transmissibility curve,” added Dr. Platus. “Vibration transmissibility is a measure of the vibrations that are transmitted through the isolator relative to the input vibrations. Every isolator will amplify at its resonant frequency, and then start isolating. Negative-Stiffness isolators resonate at 0.5 Hz – and in some cases at lower frequencies both vertically and horizontally. At this frequency there is almost no energy present. It would be very unusual to find a significant vibration at 0.5 Hz. Vibrations with frequencies above 0.7 Hz⃰ are rapidly attenuated with increases in frequency. When adjusted to 0.5 Hz, Negative-Stiffness isolators achieve approximately 93 percent isolation efficiency at 2 Hz; 99 percent at 5 Hz; and 99.7 percent at 10 Hz.”

Some low-height Negative-Stiffness isolators provide natural frequencies of 1.5 Hz horizontal and 0.5 Hz vertically. Negative-Stiffness isolators have the flexibility of custom tailoring higher resonant frequencies when lower ones are not required.

(*Note that for an isolation system with a 0.5 Hz natural frequency, isolation begins at 0.7 Hz and improves with increase in the vibration frequency. The natural frequency is more commonly used to describe the system performance.)

Location Flexibility

Just as ezAFM+ has been designed for adaptability, so has its vibration isolation platform. Negative-Stiffness permits any typical lab table to be used to achieve excellent vibration isolation. Because of its very high isolation efficiencies with low-hertz vibrations in both vertical and horizontal vectors, Negative-Stiffness vibration isolation enables sensitive instruments, like ezAFM+, to be located wherever a production facility or laboratory needs to be set up, whether that be in a basement, or on a building’s vibration-compromised sixth floor.

Negative-Stiffness isolators do not require electricity or compressed air. There are no motors, pumps or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode.

If equipment can be isolated from vibrations without having to deal with compressed air or electricity, then it makes for a system that is simpler to transport, and easier to set-up and maintain. For portability, Negative-Stiffness vibration isolation makes a complimentary match with ezAFM+.

“Since its release, ezAFM+ has become the practical low-dimensional materials characterization system in the United States,” added Schuyler. “And the Negative-Stiffness isolator is a standard, critical component of the system.”

www.minusk.com