PLE Series: Ultra-compact Power Inductors for Wearable Devices and Other Applications Using Small Batteries

The PLE series metal power inductors are high-efficiency, ultra-compact components with low leakage magnetic flux that are effective when operating with small batteries installed in wearable devices.

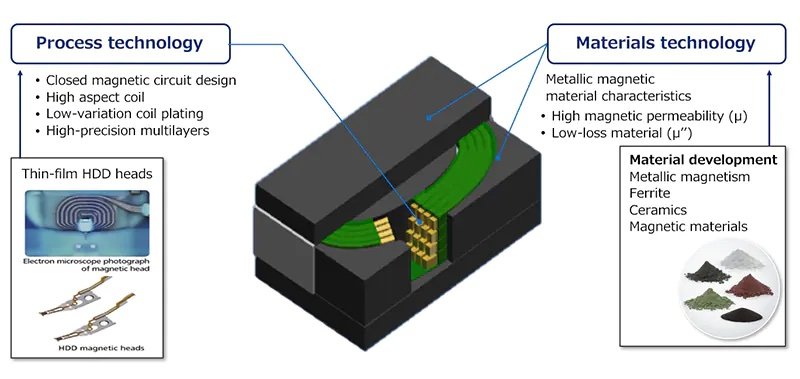

Figure 1: Key PLE technologies

By using TDK original structural designs and newly developed materials as well as thin-film processes, rated current of 500 mA with high impedance of 2.2 μH is achieved in a component with a size of L: 1.0 × W: 0.6 × H: 0.7 mm.

This chapter explains the structure and characteristics and provides other useful information including applications.

Key technologies of the PLE series

The PLE series is achieved using two key technologies. The process technology is based on thin-film HDD head technology, and by enhancing the high-precision multilayer technology, TDK has achieved inductance values of 2.2 μH and higher in a metal power inductor that is 1.0 x 0.6 x 0.8 mm in size. In addition, as a materials manufacturer, TDK has been developing various materials and developed new metallic magnetic materials with high magnetic permeability and low loss, resulting in a low-loss, high-efficiency inductor.

Process technologies/thin-film techniques

One of the key technologies of the PLE series is the thin-film process, a processing technology. The thin-film method has the following features.

- Achieves high-precision multilayering, which enables control of variation.

- Achieves double or higher winding/layers, which enables high inductance with a small conductor area.

- Magnetic material thickness can be secured on the top and bottom to reduce leakage magnetic flux.

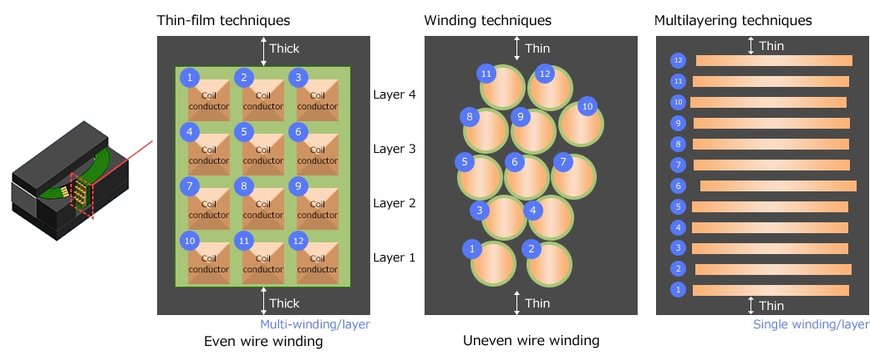

Figure 2 shows a comparison of the thin-film method with the winding method and the multilayer method, which are typical methods used for inductors.

Figure 2: Characteristics of thin-film techniques

Materials technology

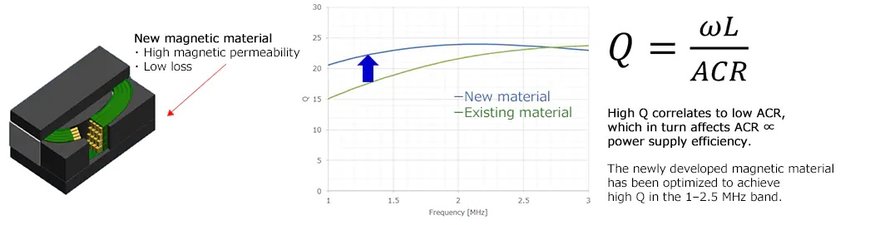

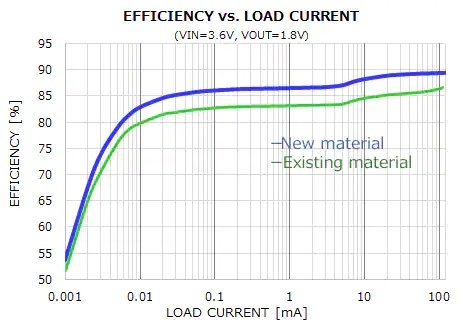

The other key technology of the PLE series is materials technology. The newly developed metallic magnetic material with high permeability and low loss has been optimized to achieve high Q in the 1–2.5 MHz band. The higher the Q, the lower the ACR, and as a result, it is possible to achieve high power supply efficiency.

Figure 3: Characteristics of new magnetic material

Hi-Q characteristic effects in a PFM

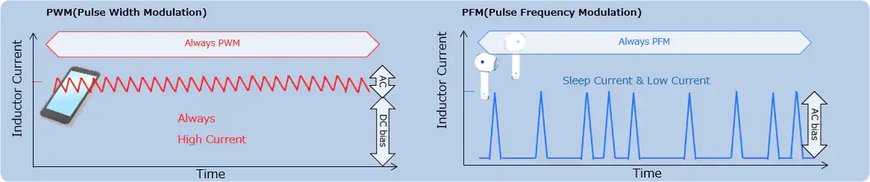

Wearable devices powered by small batteries require low power consumption, so Pulse Frequency Modulation (PFM) is used as the power supply drive method.

PFM has the advantage of lower power consumption due to lower DC bias current compared to Pulse Width Modulation (PWM), but has higher AC bias current. (Figure 4)

Therefore, the ACR characteristic becomes important, and by using Hi-Q, low-ACR inductors, it is possible to achieve high power supply efficiency. (Figure 5)

Figure 4: Comparison of PFM and PWM

Figure 5: Difference in power supply efficiency in PFM

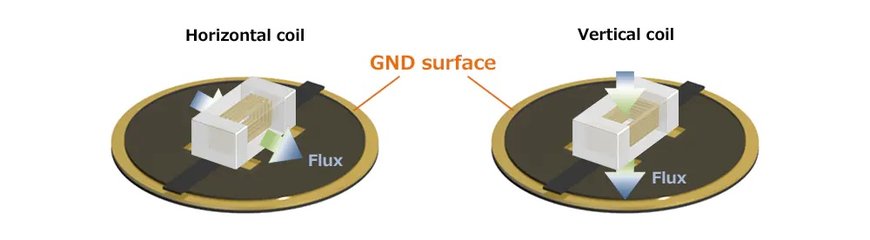

Effective against leakage magnetic flux and noise

The PLE series easily secure the thickness of the magnetic material, reducing the leakage magnetic flux. In addition, by orienting the magnetic flux generated by the coil horizontally with respect to the board, it is possible to suppress the influence of the magnetic flux that causes noise on the GND surface, suppressing noise. Figure 6 shows the results of measuring the effect of magnetic flux on the board GND surface from horizontal and vertical coils.

Figure 6: Effects of magnetic flux on the ground surface

Main applications

- A small device that uses a small battery and a DC-DCconverter to create a highly efficient circuit

- Wearable devices mentioned above

- Devices that need to be lightweight mentioned above

Main characteristics and benefits

- High magnetic permeability and low loss metal materials

- Thin-film multilayer inductors with high multilayer precision

- High inductance in an ultra-compact component

- Low noise from magnetic flux flow parallel to the GND surface

Main specifications

- Model No. :PLEA67BBA2R2M-1P

- Product size :1.0(L) x 0.6(W) x 0.8(T) mm

- Inductance :2.2uH ± 20%

- DCR :510mΩ typ.

- Q @1MHz :Vac=0.2V 18~20