Addressing electrification needs for the 21st century to achieve a net-zero future

In the 20th century, electricity was generated centrally at large power generating stations primarily by burning fossil fuels such as coal.

20th century energy networks

The electricity was then transported over long distance transmission networks and supplied to users via local distribution networks. Similar energy infrastructure emerged for transportation networks due to the proliferation of internal combustion engines (ICE) with fossil fuel as the primary source of energy transported over long distances across unstable and tenuous geographies.

Although this energy and transportation infrastructure served its purpose and industrialized most of today’s developed world, it had a tremendously detrimental impact on the global environment through the increase in greenhouse emissions, resulting in a rise in global temperatures and extreme weather patterns. As emerging and frontier economies move into the industrialization phase, this centralized fossil-fuel based electricity and transportation network is not sustainable and a next generation energy network of the future is required.

21st century energy networks

Next generation energy infrastructure to industrialize emerging and frontier economies and to maintain standards of living in the developed economies must be extremely benign on the global environment. There is consensus among global scientists that we must reduce our greenhouse emission footprint to 2000 levels to limit the global rise in temperature to below 1.5oC to have a sustainable future. To achieve a sustainable energy network of the future, we at onsemi believe that 21st century energy networks will be mainly based upon renewable energy sources such as solar and wind, combined with the ability to store energy. In addition, we believe that consumption of energy must migrate to highly efficient and zero emission loads like electric vehicles (EVs) to achieve viable and sustainable energy networks.

21st Century energy networks.

The 21st century energy network both in terms of renewable energy sources like solar, wind and storage and efficient loads like EVs and inverterized motors will be enabled by power semiconductors. In the case of Solar, wind and energy storage, Insulated Gate-Bipolar Transistors (IGBTs) and Silicon-carbide (SiC) are primarily used to convert variable and intermittent energy sources to a consistent, sustainable energy network providing a zero-emission renewable energy source. For emerging EVs and charging infrastructure, both IGBTs and SiC will be the workhorse of the transportation energy network for the foreseeable future enabling a zero-emission transportation network.

For industrial, building and factory automation, inverterized and brushless DC Motors (BLDC) are enabled by IGBTs and metal-oxide field-effect transistors (MOSFETs); the same is true for human connectivity with Cloud and 5G networks. The latest generation of MOSFET technologies are enabling efficient power supplies and UPS to provide ubiquitous connectivity for the global human network. We at onsemi believe that power semiconductors will be the enabler of 21st century energy network resulting in a sustainable future.

Power Semiconductor Growth Drivers

To attain a sustainable global energy network of the future, de-carbonization and limiting of greenhouse gases is being adopted by all major economies and regions of the world with varied degrees of regulations and incentives. Driven by a combination of regulations, incentives and attractive return on investments, we expect to see a doubling in renewable energy (GW) over the next decade. Solar will be the primary driver of this growth, due to a decrease in solar PV panel costs.

In transportation networks, the main user of fossil energy and the largest carbon emitter, the pace of change to electric vehicles (EV) will accelerate due to government regulations and automakers bringing broader portfolios with longer range vehicles to market. Another factor in the acceleration of EV adoption is the decreasing fossil fuel reserves and the resulting higher costs of extraction.

As industrialization accelerates, especially in emerging and frontier economies, the use of motors is increasing. In developed countries, building and factory automation will grow to offset higher (and rising) labor costs. Regulations in this area will demand the use of more efficient motors which will also require more efficient inverters to drive them without wasting energy.

Around 45% of all electricity in the world is consumed by motors, so efficiency improvements here will have a significant impact on reducing energy consumption. The associated inverter is critical to achieving these improvements and we expect use of these devices to double over the next 10 years, in both AC and DC motor applications. While reduced operating expenses will be beneficial, the primary driver here is expected to be more stringent efficiency legislation.

Power semiconductors: The key enabler of zero emissions

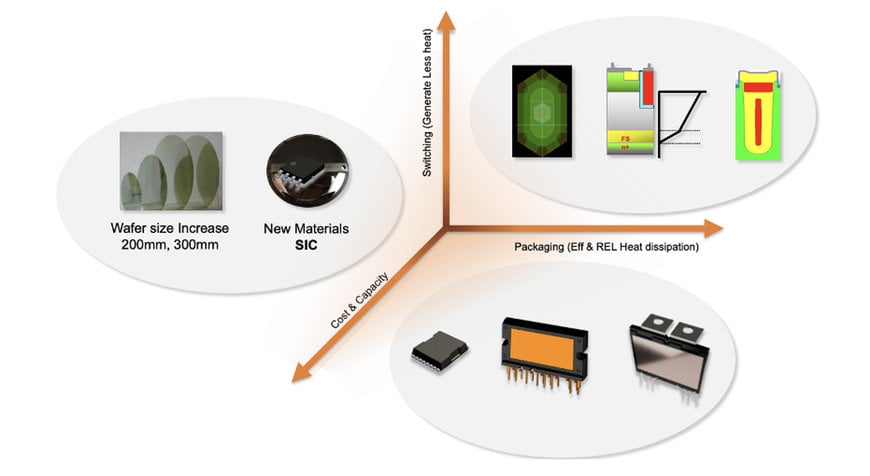

As indicated earlier, power semiconductors will be the key enabler of the 21st century energy network both for renewable energy sources and efficient loads. In order for power semiconductors to get us to continuous efficient use of energy and toward zero emissions, they will need to advance in three crucial areas:-

- Switching technology performance

- Efficient Packaging

- Cost and Capacity

The three key enablers of zero emissions.

When switching, whether the device is a MOSFET, IGBT or SiC, the key enabler will be the innovation in technology that will allow the switch to be more efficient in operation, reducing both static and dynamic losses. Efficient packaging is another key variable as, without a truly ideal switch, there will always be some losses that have to be extracted from the semiconductor die in the form of heat. From a commercial perspective, cost is always an important factor and with exponential growth in EV, renewable energy infrastructure and Cloud power, supply chain resilience for these technologies is one of the most critical factors.

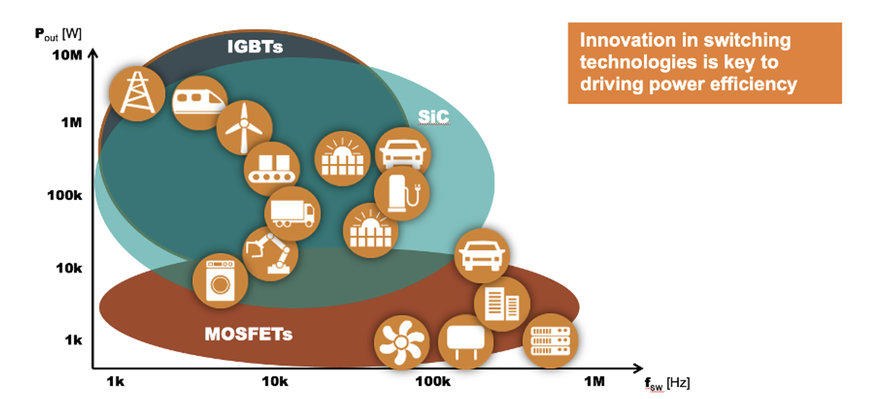

Power Semiconductor Technologies

Within semiconductor technologies, their usage is often application-specific and selection of the most optimized switching technology is based upon the power level and switching frequency to deliver highest system-level efficiency. Continuous innovation in all of these technologies is the only way to deliver the efficient and sustainable networks of the 21st century.

Switching technologies will be application specific.

Onsemi is the recognized leader in Silicon (Si) technology, industry leading MOSFETs and IGBT technologies and is investing heavily to leapfrog the competition in SiC, providing best-in-class switching technologies to the market.

SiC is a new, wide-bandgap (WBG) material that is delivering significantly improved performance over equivalent Si-based devices. The main performance driver here is in the cell structure enabling higher density. This higher cell density improves efficiency, allowing EVs to provide longer range for same battery pack.

With IGBTs, wafer thickness of the silicon wafer and the deep field stop layer become very critical to improve efficiency and increase power capabilities. For MOSFETs, cell pitch and cell density are the critical drivers. onsemi continues to drive reductions in both areas, thereby improving efficiency.

Innovation in packaging is an important consideration for extracting heat from the device, and for enhancing reliability. Depending upon the application, either a discrete device or a module may be used. In very high-power (150kW-250kW) applications such as EV, a traction module may be the best choice.

There are three key areas of innovation in packaging: interconnect, materials and modules. In the area of interconnect, moving from solder interconnect to sintering or sintering clip, enables reduction of contact resistance which, in turn, improves reliability.

Asif Jakwani, Senior Vice President & General Manager, Advance Power Division, onsemi.

In materials, the key innovations involve silver and copper sintering and eventually embedding which allows for longer life cycles and higher power density. Within the traction modules, the thermal resistance of the package is a key parameter. Here, the use of dual-sided direct cooling offers significant improvement in thermal resistance and, therefore, power density.

Alongside the technical advances in switching and packaging, onsemi provides a robust and highly resilient supply chain. Although onsemi has its Fab-lite model, it is one of very few power semiconductor companies to process their own wafers internally to deliver a robust supply chain. The recent acquisition of GT Advanced Technologies ensures that there is also a highly vertically integrated and resilient supply chain for SiC, one of the key technologies to enable sustainable growth for the future. Resilience in supply chain is enhanced through long-term partnerships with third parties including fabs and foundries.

www.onsemi.com