electronics-journal.com

13

'25

Written on Modified on

TRUMPF makes semiconductor manufacturing more efficient and precise

TRUMPF increases efficiency and precision in chip production with the TruPlasma RF Series G3, web-based control, real-time monitoring, and pulse frequencies up to 400 kHz.

www.trumpf.com

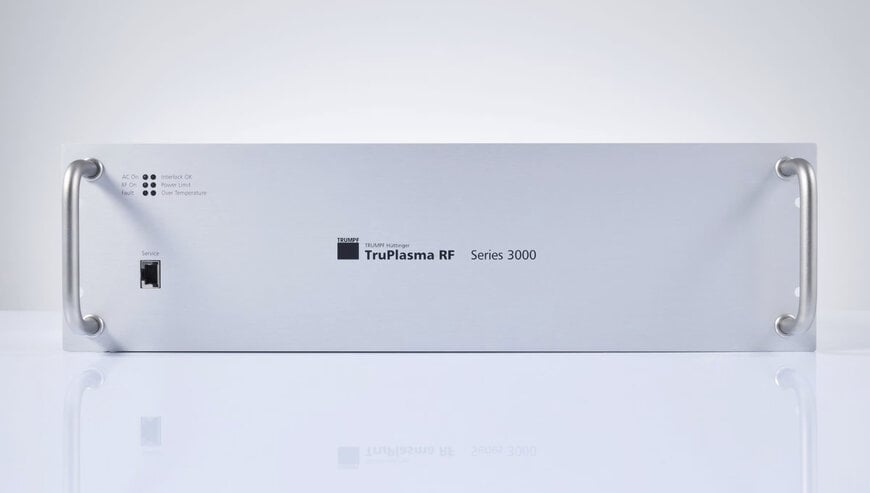

TRUMPF ensures greater precision and efficiency in semiconductor manufacturing. To this end, the high-tech company has developed a new generation of its high-frequency power supplies with the TruPlasma RF Series G3. “The system enables microchip manufacturers to achieve more stable plasma processes, thereby reducing production costs and increasing chip quality,” says Michael Ehinger, responsible for sales of electronics solutions for the semiconductor industry at TRUMPF.

Energy-efficient chip manufacturing

The modular platform offers power levels from 2.5 to 10 kW and can be flexibly integrated into existing tools. Users can also easily upgrade older tools with it. At the same time, they benefit from improved energy efficiency. The new generation of the TruPlasma RF Series G3 consumes 20 percent less power and generates less waste heat. This reduces operating costs and protects the environment.

Real-time monitoring increases quality

Users can manufacture chips more efficiently with the TruPlasma RF Series G3, thereby reducing their production costs. During plasma etching, for example, the system continuously measures the reaction of the plasma and adjusts the energy in real time. This ensures stable manufacturing processes and consistent layer quality across the entire wafer. The integrated, browser-based user interface allows all process parameters to be monitored and modified easily and efficiently during system qualification without having to install additional software.

www.trumpf.com