electronics-journal.com

16

'26

Written on Modified on

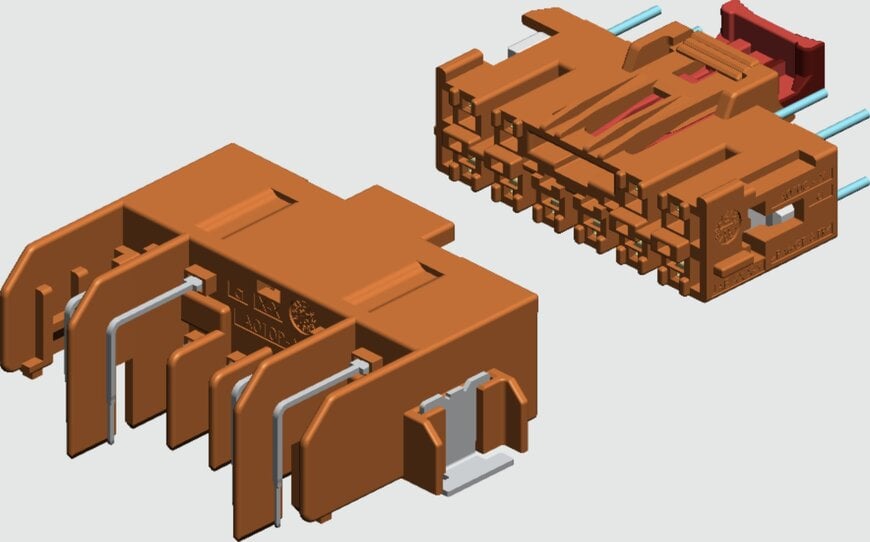

1,000 V DC connectors target compact EV BMS wiring

Rutronik adds JAE’s MY05 Series, built to IEC 60664-1 creepage/clearance requirements for high-voltage sensing and control in 800–1,000 V architectures.

www.rutronik.com

As EV platforms move toward 800 V and higher battery systems, connector design is increasingly constrained by creepage/clearance rules, limited packaging space, and automotive qualification needs. Against this background, Rutronik has expanded its connector portfolio with JAE’s MY05 Series, a compact high-voltage connector family designed for battery management systems and other high-voltage signal connections.

IEC 60664-1 design targets insulation coordination at 1,000 V DC

The MY05 Series was developed according to IEC 60664-1, focusing on optimized creepage and clearance distances for high-voltage applications. The connectors are specified for a rated voltage of 1,000 VDC and a withstand voltage of 4,800 VDC, aligning with typical insulation and safety requirements for modern EV electrical architectures.

The series is positioned for use in 800 V and 1,000 V vehicle platforms, where high-voltage monitoring and control lines must be routed through compact zones without compromising dielectric spacing.

Pin counts and terminal options for OEM layout flexibility

JAE’s MY05 connectors are available in 10-pin and 14-pin variants. For layout and supply-chain flexibility, designers can select between:

- MX80-compatible crimp terminals, or

- 0.63 mm EU-standard terminals with a common pin header

An optional CPA (Connector Position Assurance) mechanism is offered to add a secondary locking function during mating.

Automotive test standards and -40 °C to +125°C operating range

For vehicle-grade robustness, the series is tested against major automotive connector standards including USCAR-2, USCAR-37, LV214, and LV215. The operating temperature range is specified from -40 °C to +125 °C, supporting typical underbody and battery enclosure conditions.

Through-hole headers designed for reflow and pin-in-paste processes

The connector pin headers are offered in straight and right-angle through-hole versions. Both are designed for pin-in-paste / reflow soldering workflows, which helps align the connectors with high-volume PCB assembly processes used in EV electronics and power control units.

Typical use cases: BMU/BCU links and high-voltage sensing lines

The MY05 Series is aimed primarily at Battery Management Systems (BMS) in EV battery packs—especially connections between BMU, BCU, and cell modules. Additional use cases include high-voltage sensing and control wiring in next-generation EV platforms.

Beyond automotive, the connectors are also positioned for high-voltage industrial equipment, where compact insulation-coordinated interconnects are needed for monitoring and control circuits.

www.rutronik.com

Automotive test standards and -40 °C to +125°C operating range

For vehicle-grade robustness, the series is tested against major automotive connector standards including USCAR-2, USCAR-37, LV214, and LV215. The operating temperature range is specified from -40 °C to +125 °C, supporting typical underbody and battery enclosure conditions.

Through-hole headers designed for reflow and pin-in-paste processes

The connector pin headers are offered in straight and right-angle through-hole versions. Both are designed for pin-in-paste / reflow soldering workflows, which helps align the connectors with high-volume PCB assembly processes used in EV electronics and power control units.

Typical use cases: BMU/BCU links and high-voltage sensing lines

The MY05 Series is aimed primarily at Battery Management Systems (BMS) in EV battery packs—especially connections between BMU, BCU, and cell modules. Additional use cases include high-voltage sensing and control wiring in next-generation EV platforms.

Beyond automotive, the connectors are also positioned for high-voltage industrial equipment, where compact insulation-coordinated interconnects are needed for monitoring and control circuits.

www.rutronik.com