electronics-journal.com

21

'26

Written on Modified on

ASMPT introduces the SIPLACE V platform, redefining high-performance SMT placement

Up to 30% higher output with maximum flexibility, compact footprint, and long-term investment protection.

smt.asmpt.com

With a footprint of just 1.1 × 2.4 meters, the new SIPLACE V gives electronics manufacturing a decisive boost – not only in real performance, but also in quality, flexibility, and future readiness.

Source: ASMPT

ASMPT SMT Solutions, the global market and technology leader in integrated hardware and software solutions for electronics manufacturing, has unveiled the new SIPLACE V platform—a placement solution engineered from the ground up to meet the rising performance, quality, and flexibility demands of modern electronics production.

The SIPLACE V platform delivers up to 30% higher real-world performance, combining maximum speed with exceptional placement accuracy and process reliability. Thanks to a newly developed machine frame, highly efficient linear drives, and measurement systems with improved resolution, the platform achieves significantly higher accelerations and precision under realistic production conditions. These advances make SIPLACE V particularly well suited for demanding sectors such as automotive electronics, consumer electronics, smartphones, IT, networking, and emerging AI applications.

Proven performance in real production environments

Field deployments have confirmed that the performance gains extend well beyond theoretical benchmarks. In high-mix, low-volume environments characterized by frequent changeovers and high variant diversity, SIPLACE V has demonstrated consistent productivity gains while maintaining the highest quality standards.

Martin Zistler, Vice President Global Engineering at Zollner Elektronik AG, notes that after millions of components placed in production, the platform has proven its strengths in performance, flexibility, quality, and effective output under real manufacturing conditions.

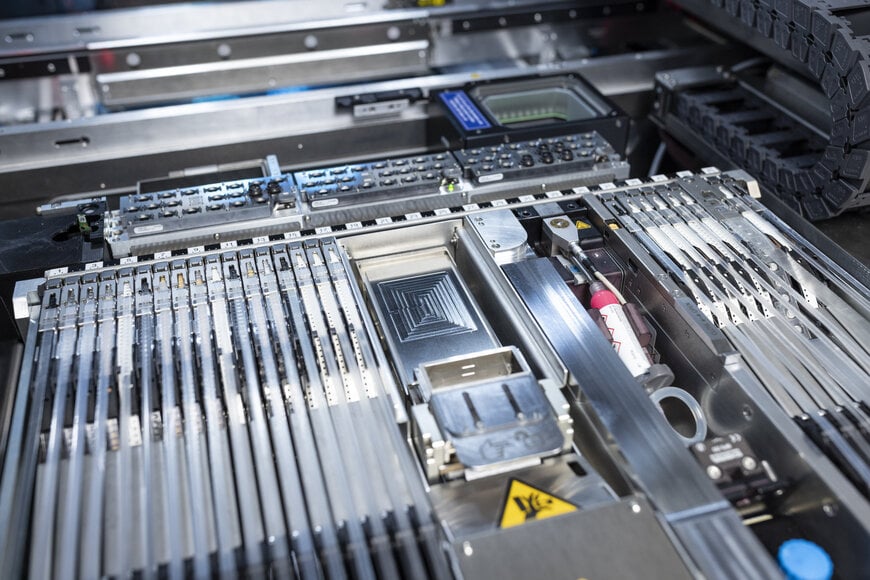

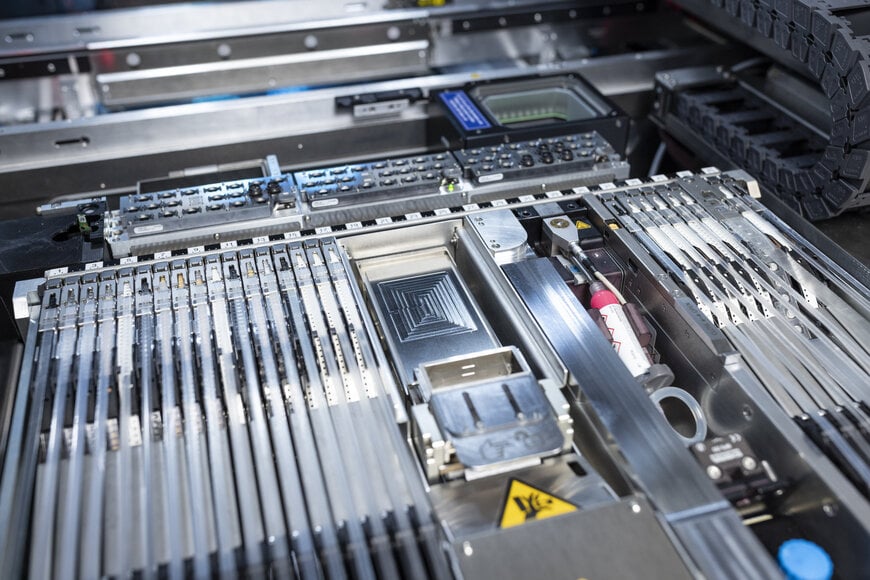

45 available 8 mm slots per location – constant, regardless of the selected options. All existing X-Feeders remain fully compatible, including the Linear Dipping Unit, Power Connector, as well as the SIPLACE Glue Feeder and SIPLACE Measuring Feeder.

Source: ASMPT

New generation of placement heads

A key contributor to the platform’s performance boost is the latest generation of placement heads:

Source: ASMPT

ASMPT SMT Solutions, the global market and technology leader in integrated hardware and software solutions for electronics manufacturing, has unveiled the new SIPLACE V platform—a placement solution engineered from the ground up to meet the rising performance, quality, and flexibility demands of modern electronics production.

The SIPLACE V platform delivers up to 30% higher real-world performance, combining maximum speed with exceptional placement accuracy and process reliability. Thanks to a newly developed machine frame, highly efficient linear drives, and measurement systems with improved resolution, the platform achieves significantly higher accelerations and precision under realistic production conditions. These advances make SIPLACE V particularly well suited for demanding sectors such as automotive electronics, consumer electronics, smartphones, IT, networking, and emerging AI applications.

Proven performance in real production environments

Field deployments have confirmed that the performance gains extend well beyond theoretical benchmarks. In high-mix, low-volume environments characterized by frequent changeovers and high variant diversity, SIPLACE V has demonstrated consistent productivity gains while maintaining the highest quality standards.

Martin Zistler, Vice President Global Engineering at Zollner Elektronik AG, notes that after millions of components placed in production, the platform has proven its strengths in performance, flexibility, quality, and effective output under real manufacturing conditions.

45 available 8 mm slots per location – constant, regardless of the selected options. All existing X-Feeders remain fully compatible, including the Linear Dipping Unit, Power Connector, as well as the SIPLACE Glue Feeder and SIPLACE Measuring Feeder.

Source: ASMPT

New generation of placement heads

A key contributor to the platform’s performance boost is the latest generation of placement heads:

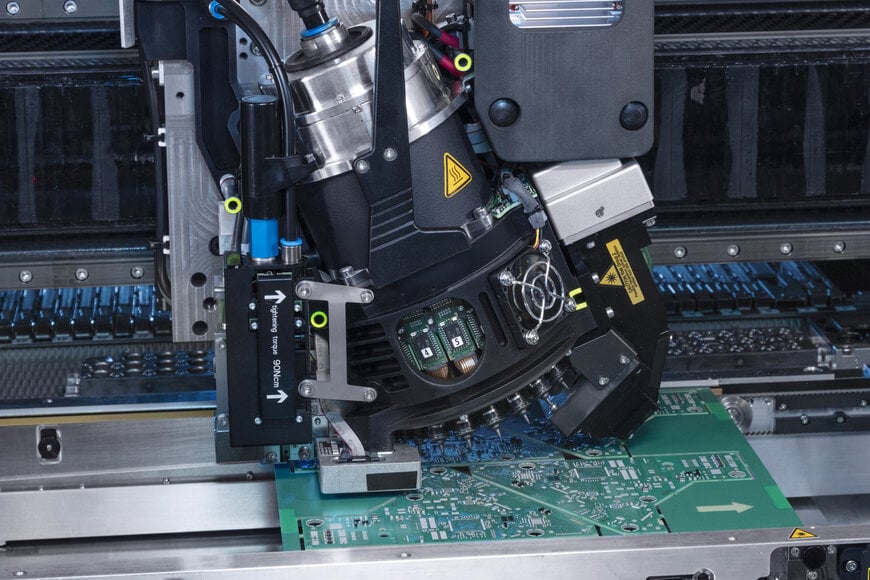

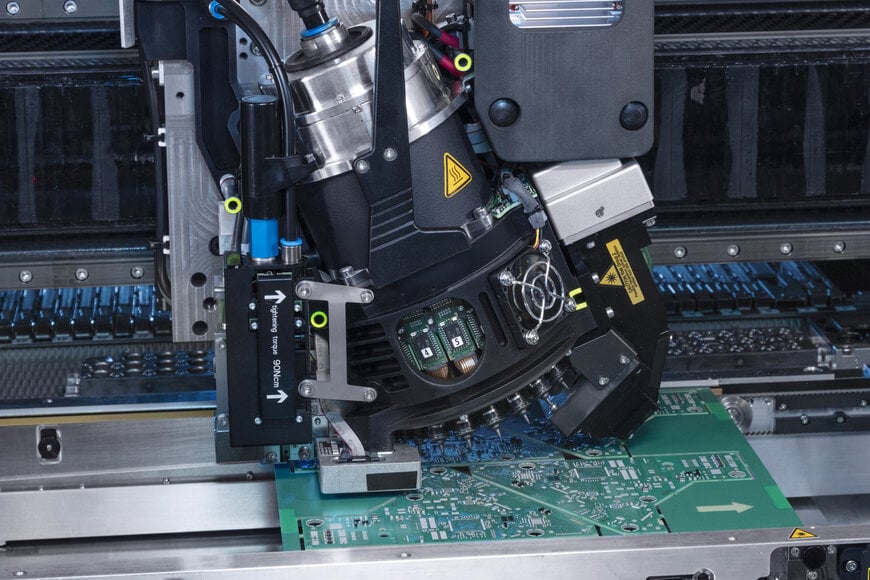

- SIPLACE CP20 collect-and-place head achieves up to 52,500 components per hour with a placement accuracy of 25 µm @ 3σ, setting a new benchmark for high-speed applications.

- SIPLACE CPP head offers software-controlled switching between collect-and-place, pick-and-place, and mixed modes, delivering up to 28,000 components per hour with placement forces up to 15 N—ideal for complex mixed-assembly scenarios.

- SIPLACE TWIN VHF head is designed for large and unusual components up to 200 × 150 × 28 mm and placement forces up to 100 N, enabling reliable assembly of advanced components such as BGAs used in AI-driven electronics.

Flexibility across the full component spectrum

The SIPLACE V platform handles everything from ultra-miniature 016008M chips to large-format and odd-shaped components. A universal head interface allows rapid head changes without stopping production. Configurable single- or dual-gantry designs, optional single- or dual-track conveyors, and advanced inspection modules such as 3D coplanarity checking ensure adaptability to a wide range of applications.

The system supports PCB sizes up to 700 × 530 mm, accommodates multiple tray units, and offers an increased number of feeder slots—without compromising existing options such as Smart Pin Support. All this capability is delivered in a compact footprint of just 1.1 × 2.4 meters, setting a new benchmark for floorspace productivity.

The new CP20 collect-and-place head has been specifically optimized for maximum performance and precision – delivering up to 52,500 cph at 25 µm @ 3σ, it sets new standards for high-speed applications in electronics manufacturing.

Source: ASMPT

Future-proof quality and investment security

Building on the proven strengths of the SIPLACE series, the SIPLACE V platform integrates features such as individually rotatable nozzle segments, comprehensive component inspection, closed-loop sensor technology, and full traceability as standard. Real-time monitoring of component heights and PCB profiles enables automatic force adjustment, ensuring consistent placement quality even at high cycle rates.

Equally important, SIPLACE V fits seamlessly into existing ASMPT SMT Solutions environments. Current feeders, cameras, and software—from station-level applications to the WORKS Software Suite and Factory Solutions—remain fully compatible. This allows manufacturers to modernize production incrementally while preserving existing investments and preparing for future automation and AI-based enhancements.

With the SIPLACE V platform, ASMPT SMT Solutions sets a new standard for performance, flexibility, and long-term security in surface-mount technology.

www.asmpt.com

The SIPLACE V platform handles everything from ultra-miniature 016008M chips to large-format and odd-shaped components. A universal head interface allows rapid head changes without stopping production. Configurable single- or dual-gantry designs, optional single- or dual-track conveyors, and advanced inspection modules such as 3D coplanarity checking ensure adaptability to a wide range of applications.

The system supports PCB sizes up to 700 × 530 mm, accommodates multiple tray units, and offers an increased number of feeder slots—without compromising existing options such as Smart Pin Support. All this capability is delivered in a compact footprint of just 1.1 × 2.4 meters, setting a new benchmark for floorspace productivity.

The new CP20 collect-and-place head has been specifically optimized for maximum performance and precision – delivering up to 52,500 cph at 25 µm @ 3σ, it sets new standards for high-speed applications in electronics manufacturing.

Source: ASMPT

Future-proof quality and investment security

Building on the proven strengths of the SIPLACE series, the SIPLACE V platform integrates features such as individually rotatable nozzle segments, comprehensive component inspection, closed-loop sensor technology, and full traceability as standard. Real-time monitoring of component heights and PCB profiles enables automatic force adjustment, ensuring consistent placement quality even at high cycle rates.

Equally important, SIPLACE V fits seamlessly into existing ASMPT SMT Solutions environments. Current feeders, cameras, and software—from station-level applications to the WORKS Software Suite and Factory Solutions—remain fully compatible. This allows manufacturers to modernize production incrementally while preserving existing investments and preparing for future automation and AI-based enhancements.

With the SIPLACE V platform, ASMPT SMT Solutions sets a new standard for performance, flexibility, and long-term security in surface-mount technology.

www.asmpt.com