electronics-journal.com

24

'19

Written on Modified on

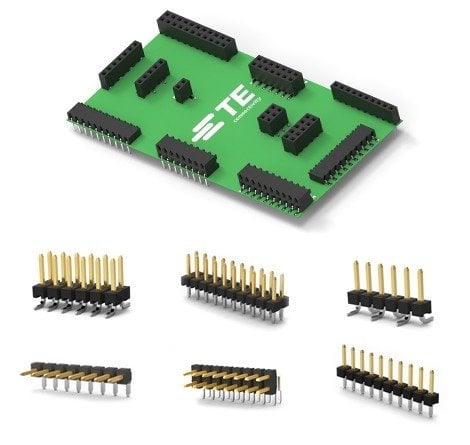

TE Connectivity introduces AMPMODU connectors with 2 mm centerlines for board signal transfers

"We are excited to be able to grow our AMPMODU portfolio to now include a 2 mm centerline offering that provides customers with a wide variety of rugged, reliable and versatile board connectors. This extension supports the trend in our industry of board miniaturization while continuing to meet the high reliability and quality standards that our customers expect from TE”

Target applications include PLC and other I/O devices, servo drives, industrial automation and controls, industrial robotics, instrumentation and test equipment, and building and home automation devices. The new 2 mm offerings will include breakaway headers and board-to-board receptacles, both supporting automated surface-mount, through-hole reflow (Pin-in-Paste), and traditional through-hole mount processes for ease of manufacturing.

The 2 mm breakaway headers can be mounted onto boards with thicknesses of 1.6 mm and 2.4 mm, providing customers with a wide range of options for PCB assembly. Through-hole headers feature straight or right-angle posts with a mating post length of 4.0 mm (0.16 inch) and a lead length of 2.8 mm (0.11 inch) and several other lead lengths, depending on board thickness and soldering method.

They are molded in a flame retardant (UL94 V0) thermoplastic housing material that is resistant to reflow soldering temperatures and provides a high level of safety in harsh environments. The product offering includes single and double row variants and is available in bulk, tube, and tape and reel packaging offering flexibility in manufacturing. Shrouded headers are under development and will come to market in the near future.

The 2 mm board-to-board receptacles are housed in a high-temperature-resistant liquid crystal polymer (LCP) and utilize phosphor bronze contacts with dual cantilever beams that are available in three gold plating thicknesses. The dual-beam design provides for increased contact surface between the header pin and the receptacle contact to allow reliable signal transfers. The complete portfolio includes various top- and dual-entry vertical and horizontal receptacles that offer multiple options for board-to-board stacking of header and receptacle combinations.

“We are excited to be able to grow our AMPMODU portfolio to now include a 2 mm centerline offering that provides customers with a wide variety of rugged, reliable and versatile board connectors. This extension supports the trend in our industry of board miniaturization while continuing to meet the high reliability and quality standards that our customers expect from TE,” says Sameer Trikha, global product manager for TE’s Board Signal products.

ABOUT TETE Connectivity Ltd. (NYSE: TEL) is a $14 billion global technology and manufacturing leader creating a safer, sustainable, productive, and connected future. For more than 75 years, our connectivity and sensor solutions, proven in the harshest environments, have enabled advancements in transportation, industrial applications, medical technology, energy, data communications, and the home. With 80,000 employees, including more than 8,000 engineers, working alongside customers in approximately 140 countries, TE ensures that EVERY CONNECTION COUNTS.

www.te.com