electronics-journal.com

12

'20

Written on Modified on

Cognex News

The potential for machine vision inspection is growing rapidly

An Interview of Thierry Lelaure, VP of Sales (Europe) at Cognex Corporation. By Milton D'silva.

What are the most recent developments in machine vision at Cognex?

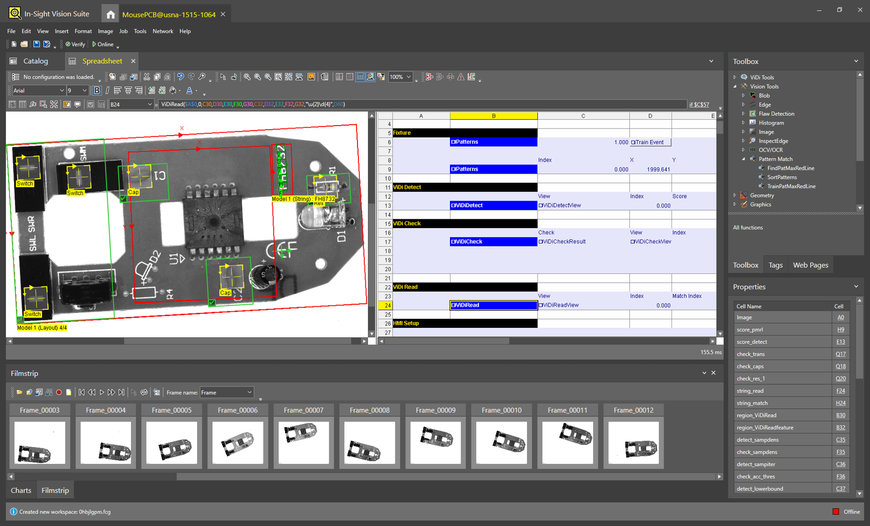

Common machine vision application examples include guiding a robot to put a windshield in a car, aligning a screen on a smartphone, reading alphanumeric codes and barcodes on packages, gauging or measuring the width of an automotive break pad, or inspecting electronic components for defects.

The potential for machine vision inspection is growing rapidly due to developments in deep learning based vision. Tasks that were very difficult or impossible to perform with state-of-the-art rules-based vision a few years ago are now possible using deep learning techniques. This has the potential to broaden our market significantly and replace millions of visual inspectors in coming years.

Today, tens of thousands of people perform difficult, tedious and error-prone visual inspections for flaws and defects on electronic components and subsystems which will be done more reliably and at lower cost in the future with deep learning-based machine vision.

In a world where lights-out manufacturing, plants without human operators, is increasingly something being envisioned, deep learning vision is perhaps the most important single technology in getting there.

SUALAB brings considerable IP, engineering expertise and market coverage in the area of AI and deep learning-based vision inspection. The acquisition of SUALAB accelerates the opportunity for Cognex to solve challenging inspection applications in factories, which (until now) could only be done by large teams of human visual inspectors. Additionally, SUALAB expands Cognex’s presence in Asia, which is the world’s largest and fastest-growing market for deep learning-based vision.

The addition of SUALAB’s engineering team and intellectual property significantly enhances Cognex’s existing deep learning capabilities acquired from ViDi Systems in April of 2017. We now have the world’s largest team of highly skilled AI and deep learning engineers specialising in industrial machine vision applications. This special domain knowledge provides immense value to Cognex in one of our fastest-growing markets.

What are the factors that will assist machine vision market growth in the near future?

There are several macro-trends driving future adoption of machine vision.

The first is rising wages. Factory workers are paid more and hourly wages are rising faster than productivity in most factories. Customers often can find the staff they need to run their factories.

There's also a desire for faster throughput. Every company wants to get more production out of its lines and wants to increase the number of different products they make on each line.

There’s an ever-increasing emphasis on quality. The cost of quality is being measured more actively and vision is an increasingly important means to measure, understand, and improve it.

Traceability is an area where our customers are concerned about the loss of revenue and reputation that comes with diversion and counterfeiting of their products. Machine vision technology is increasingly applied to read and validate unique identifiers on products to prevent counterfeiting and diversion.

Next, products and their components are getting smaller and smaller. Successive generations of electronics of becoming too small for human hands to assemble, so their processes are becoming automated and manufacturers increasingly seek to apply barcodes to all components. The barcodes they apply can be the width of a human hair, too small to see with the naked eye, and often only readable with machine vision.

A similar dynamic exists in our own machine vision products, which like all technology, is becoming smaller, less expensive, more powerful, and easier to use and integrate. 10 years ago, the cost and complexity of implementing machine vision meant it was only adopted by very sophisticated customers with large highly-skilled engineering teams, primarily in the semiconductor, automotive, and electronics industries. Today, entry level machine vision products can be purchased for as little as $1,000 and set up by almost anyone. This has led to their rapid adoption by manufacturers of food, beverage, and consumer products.

And lastly, there’s a trend known as the Amazon effect. The retail industry is being disrupted by e-commerce where the ability to deliver rapidly and cost-effectively is defining who wins. Amazon now ships over ten billion packages a year, is forward and backward integrating into air freight and local delivery, and competitors are investing billions in logistics infrastructure and automation to remain relevant.

What are the emerging trends in machine vision applications due to greater adoption of industry 4.0?

Manufacturers want easy access to data collected from the factory floor. Cognex vision systems are used in the manufacture of over 2 billion products a day, capturing and analysing multiple digital images of each of them. We're focused on connecting our vision systems to help customers access this data in real time to make more informed decisions and help with things like predictive maintenance, remote monitoring and device management.

How is the impact of Covid-19 likely to shape the trends in machine vision?

Manufacturers are increasingly interested in how robotics and automation can help their business, both from a production and workforce augmentation standpoint. Machine vision is an efficient and effective way for manufacturers to automate processes such as visual inspection and defect detection.

Ecommerce was one of the fastest growing markets for machine vision before the pandemic. Demand in this market is increasing even faster now due to social distancing, as consumers are ordering more goods online to avoid shopping in-person. As a result, e-retailers are turning to technology to help them be as efficient as possible in their distribution efforts.

Many companies are also looking at their manufacturing operations to see how they can become more flexible and agile with the packaging of products so they can go straight-to-consumer, because there isn’t time for products to be tied up in the logistics chain.

www.cognex.com