Yaskawa launches AC Servo Drive Σ-X Series to Enhance Customers’ Added Value with the Industry’s Best Motion Performance and Digital Data Solution

Yaskawa Electric Corporation (Head Office: Kitakyushu City, Fukuoka Prefecture; Representative Director and President: Hiroshi Ogasawara) is pleased to announce the launch of the AC servo drives “Σ-X Series”, the successor to the reputed “Σ-7 Series”.

AC Servo drive “Σ-X Series"

1.Aim of commercialization

We first commercialized the AC Servo Drive “Σ Series” in 1992, the first fully digital servo system in the industry. Since then, the system has been well received by many customers due to its higher performance, higher functionality, and smaller size.

The Σ series evolved in response to changing customer needs with “Σ-II Series” in 1997, “Σ-III Series” in 2002, “Σ-V Series” in 2007 and “Σ-7 Series” in 2013.

As a successor to the “Σ-7 Series”, we have developed the “Σ-X Series”, which adds the functions of utilizing sensing data, as well as the further advanced functions and performance. We aim to create added value together with our customers and to realize “providing high added value to customers such as motion control +α” and “consolidating the i³-Mechatronics concept and establishing a business model” based on our core technology of motion control.

2.Key Features

The Σ-X Series features “Industry’s best motion performance” and “Digital data solutions starting with servo”.

Industry’s best motion performance

・The speed response frequency, which is an important evaluation index for servo drives, has reached 3.5 kHz as the world’s highest level, by improving the ability to follow commands and ensuring stable operation, resulting to improve productivity. The maximum speed of the servomotor reaches 7000 rotations per min, increasing the driving speed of the device, shortening the tact-time and improving productivity. Equipped with an encoder with a resolution from conventional 24 bit (16 million Pulse/Rotation) to the industry’s highest level of 26 bit (67 million Pulse/Rotation), it improves stop accuracy and realizes smoother movement.

・By improving the servo adjustment function required to maximize the device performance such as high speed and high precision, it has become possible to easily perform optimum and stable servo adjustment in a short time, including mechanisms that were previously difficult to adjust.

Digital data solutions starting with servo

・For preventive maintenance of the equipment and improvement of production quality, it is important to take various data from an equipment, and a servo becomes a sensor by the data detection function which is strengthened from “Σ-7 Series”.

・With the Σ-LINK II sensor network, the encoder signal line can be connected to various sensors, I/O devices, and other devices installed on the machine side. The use of wire-saving and high-speed sensor data synchronized with the encoder enables the system to achieve higher functionality and performance.

・In order to detect equipment abnormalities in advance, Σ-X has various sensing functions as well as environmental and lifetime monitoring. Σ-X can detect abnormalities by monitoring changes in the device.

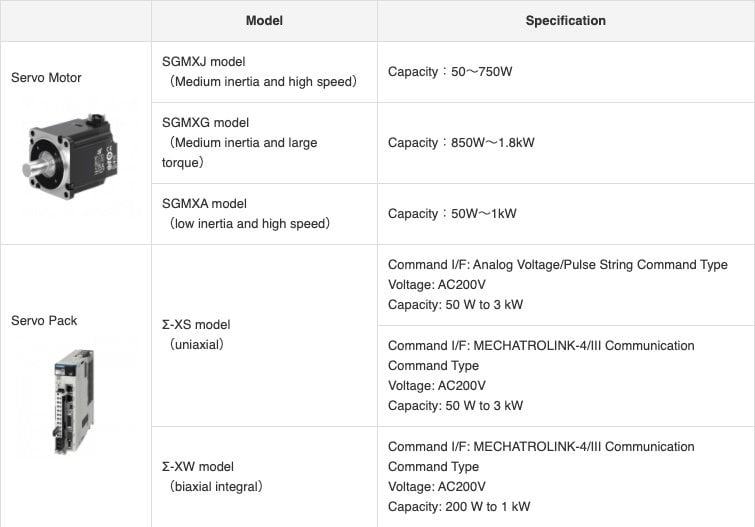

3.Product lineup

In March 2021, we plan to start receiving orders for three models of servo motors and two models of servo packs, and thereafter expand the lineup as appropriate. The capacity up to 15 kW is scheduled to be available by March 2022.

4.Main Applications

- “Device”

- Semiconductor and LCD manufacturing equipment

- Electronic component mounting machine

- Machine tool

- Metal processing machine

- Packaging machine

- Industrial robot

- Other general industrial machinery