electronics-journal.com

13

'23

Written on Modified on

Keeping Automotive Challenges in Check

By Stuart Cording, for Mouser Electronics.

Automotive is a fascinating branch of electronics. Thanks to improvements in manufacturing techniques and quality, a vehicle can last for 200,000 miles (320,000 km). This means more than a decade of operating under exceptionally challenging environmental conditions, from the summer heat of Athens in Greece to the freezing winters of Kautokeino in Norway. To make this happen, semiconductor vendors build parts designed for vehicle use or offer standard designs that complete additional validation to meet the automotive industry’s needs.

Once designed into electronic control units (ECU), these systems undergo what, to outsiders, must seem like bizarre and perhaps over-zealous testing regimes. However, every test has its reason. Most are developed after analyzing returned vehicles in great detail to understand the failure mode. After all, no one wants a premium product costing tens of thousands of Euros, Dollars, or Pounds to be returned because an electric mirror stopped working after a month. To support those designing, testing, and maintaining our cars, the test and measurement industry provides a wide range of equipment dedicated to getting and keeping our favored transport method moving.

Cranky, Droopy Supply Tests

While on the wane, internal combustion engines still make up a significant portion of car sales each year. The effort required to turn the engine over when starting, known as cranking, is significant, with many amps flowing to the electric starter motor. And, thanks to fuel-saving technology such as Start-Stop, this occurs far more frequently than it did in the vehicles of yesteryear. Due to the surge of current drawn, the supply voltage across kilometers of wiring tends to sag or droop, disrupting the operation of ECUs. Because of this and other in-vehicle failure modes, the automotive industry has a broad range of standards against which suppliers must test their products.

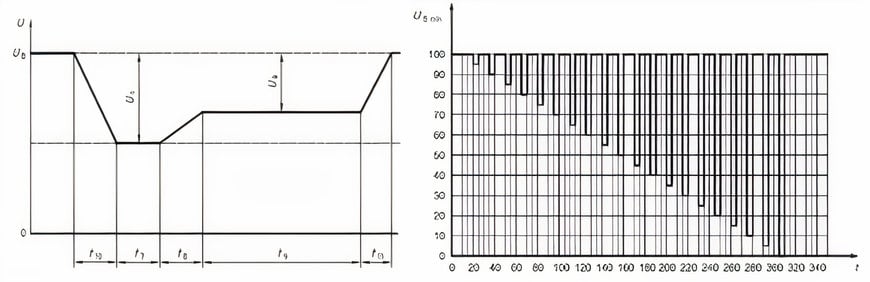

ISO 7673-2 includes the negative pulses that occur due to inductive loads, with spikes that fall to more than -75 V within one microsecond, and positive pulses resulting from removing loads that peak at 112 V. Then, in ISO 16750-2:2012, complex voltage profiles are designed to reflect the supply when a vehicle is started.

These tests are challenging to program in standard power supplies, but equipment such as the B&K Precision 9115-AT generate these supply line transients and discontinuities as part of their feature set. Delivering a maximum power of 1,200 W over 0 to 80 V and 0 to 60 A, the 9115-AT intelligently ranges current and voltage to stay within its safe area of operation.

The front panel of this 1U rack-mounted supply provides a numerical keypad, an easy-to-read vacuum fluorescent display (VFD), and rotating knobs for simple configuration of the output and functionality. At the rear are the remote sense terminals, fans, and analog and digital control interfaces (GPIB, RS-232, RS-485, USBTMC-compliant USB). Naturally, the unit can also be controlled via software such as LabVIEW. Profiles for testing automotive systems are also included. These range from the injection of supply line transients as per ISO 7637 to the drops and discontinuities of ISO 16750-2:2012.

Various ISO standards describe power supply sequences and discontinuities that automotive electronic control units (ECU) should be able to withstand. (Source: B&K Precision)

Finding Automotive Faults

Flickering lights, fuses that blow regularly, and lamp clusters that glow even when turned off are just some of the electrical issues drivers can have with their cars. However, with kilometers of cable to check, finding the one at fault is challenging. Then there are effects of the environment, leading to corroded connections and challenges with accessing a conductor in a connector. The Fluke 88 Series V/A Automotive Meter Combo Kit is ideal for those working in, under, and around the vehicle, searching out the cause of electrical issues.

Like any Fluke product, this handheld unit is protected from falls by its yellow removable holster featuring built-in test lead and probe storage. And, with a 600 mV to 1000 V and 60 mA to 10 measurement range for both DC and AC, it’s ready to tackle all automotive measurement needs. It also includes an ohmmeter (600 Ω to 50 MΩ).

The key differentiator to a standard multimeter is the range of probes and extras. The RPM80 Inductive Pick-Up probe is perfect for making RPM measurements, while the TPAK Magnetic Hanger ensures both hands are free to hold the probes. There are also TP220 probes that are suitable for corroded terminals, alligator clips, and the 80BK temperature probe. Optional extras include insulation piercing and back probe pins as well as a pressure vacuum transducer.

The Fluke 88V/A couples the recognizable robust yellow multimeter with probes, cables, and sensors suited to daily measurements on vehicle electrics. (Source: Fluke)

Examining Data Buses

Many of the wires in the cable loom of a car carry data, supporting a variety of serial protocols that target different automotive applications. Controller Area Network (CAN), developed in the 1980s by Bosch, provides a robust serial interface that links central ECUs with vehicle functions such as electronic parking brakes, start/stop, and parking assist systems, to name just a few. Requiring two wires, microcontrollers with a dedicated CAN peripheral, and a transceiver, this automotive network can prove too complex or expensive for some applications.

LIN, or Local Interconnect Network, is a single wire bus operating at up to 19.2 Kbits/s over up to 40 m of cable. Needing only a standard UART serial interface and a suitable transceiver, LIN is often used in comfort features, ambient lighting, and electric motor controllers, applications where CAN would be considered overkill. Finally, FlexRay provides an interface with more bandwidth than CAN and better determinism. It targets x-by-wire systems for steering and braking.

Mixed-signal (MSO) and mixed domain oscilloscopes (MDO), with their combination of analog and digital capture, enable developers to examine the details of what is going on in complex ECUs. However, the decoding and analysis of automotive networks require an upgrade, such as the DPO4AUTO for the MDO4000C Series from Tektronix. Once installed, the oscilloscope can capture CAN or LIN data on the analog or digital channels, supporting CAN, CAN-FD, LIN 1.x, and LIN 2.x.

Decoding these protocols is simplified thanks to unique coloring of start, sync, identifier, data, bit-stuffing errors, and checksums, to name a few. The content of data packets can also be used to trigger the oscilloscope. The MDO4000C Serial Application module supports searching through packet data, allowing users to zone in on the problematic area to speed up issue resolution. A tabular display of captured bus data is also supported.

The DPO4AUTOMAX additionally includes support for FlexRay, while PC-based software offers eye-diagram analysis from the acquisitions plotted against the TP1 mask as defined in the standard. For those with WaveSurfer 4000HD oscilloscopes from Teledyne LeCroy, a similar upgrade supporting all three automotive bus systems is available as WS4KHD-AUTO TD.

Keeping Tabs on Temperature

Vehicles get very hot, both inside the cabin and under the hood. Monitoring all possible locations at once can be difficult, with data acquisition (DAQ) systems quickly running out of channels. However, with cheap computing available in the form of Raspberry Pi and plenty of storage for logged measurements, this can be overcome easily. The Digilent MCC 134 is a Thermocouple DAQ HAT that stacks up to eight high on the Raspberry Pi header.

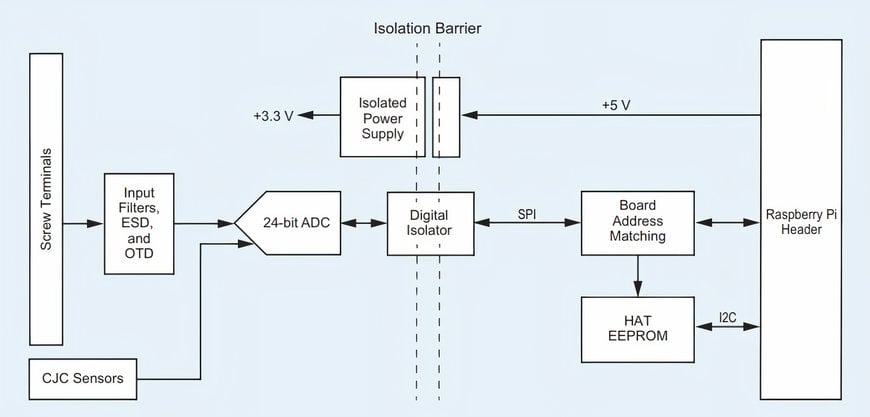

The MCC 134 is a Raspberry Pi HAT from Digilent that support four thermocouples and can be stacked up to eight high.

The HAT features screw terminals for up to four thermocouples (TC) that are converted using a differential input 24-bit A/D converter. The unit also includes cold junction compensation and linearization and monitors the TCs for open connections that can are reported using the available software. Power is drawn directly from the header. Due to the heat generated by the Raspberry Pi, it is recommended to use a small fan to ensure airflow that will reduce measurement errors in the HAT placed closest to the processor.

Block diagram of the MCC 134 HAT, showing A/D converter and cold junction compensation together with I2C EEPROM for board configuration.

Like all such platforms, a host of software examples are available for C, C++, and Python hosted on GitHub. An If-This-Then-That (IFTTT) trigger service is also available, written in Python. Comprehensive installation instructions are included with the repository. Compatible TCs include J, K, R, S, T, N, E, and B.

A Test Tool for Every Automotive Challenge

The automotive environment delivers a wealth of challenges to developers building new vehicles and those who maintain and repair them once they’re on the road. Power lines in automotive are especially noisy, and the expectations of ECU performance under these conditions seem extreme to the uninitiated. Programmable power supplies that can simulate all current standard test profiles are ideal to prove compliance in the laboratory. Multimeter kits for automotive provide all the essential probes and transducers, ensuring measurements can be made even at the most corroded connectors. For those struggling with automotive networks, oscilloscope upgrades allow not only decoding but also triggering on data and protocol errors. Together with other signals, they help teams quickly locate the cause of issues. Finally, temperature is a big challenge in automotive. Should your DAQ have reached its limits, a HAT extension coupled with a Raspberry Pi might just provide the solution to logging thermal highs and lows during a test drive.

www.mouser.com