Revolutionizing PCB Manufacturing with AI-Powered Quality Inspection

How Huseyn Gasimov's Automated Visual Inspection Prototype is Transforming Production Processes.

www.intelec.ai

Automation is becoming increasingly crucial in PCB manufacturing. Surprisingly, it is still not something that is being used widely across the industry. As it stands, many PCB companies rely on manual visual inspection, a time-consuming process which can leave companies struggling to meet throughput, yield and quality targets.

Huseyn quickly found this out when he started building Intelec AI while working as a data scientist at Roche, a major diagnostics and pharmaceutical company. Initially starting with software, he added consulting and then realized the true competitive advantage was in being able to develop bespoke hardware for his customers.

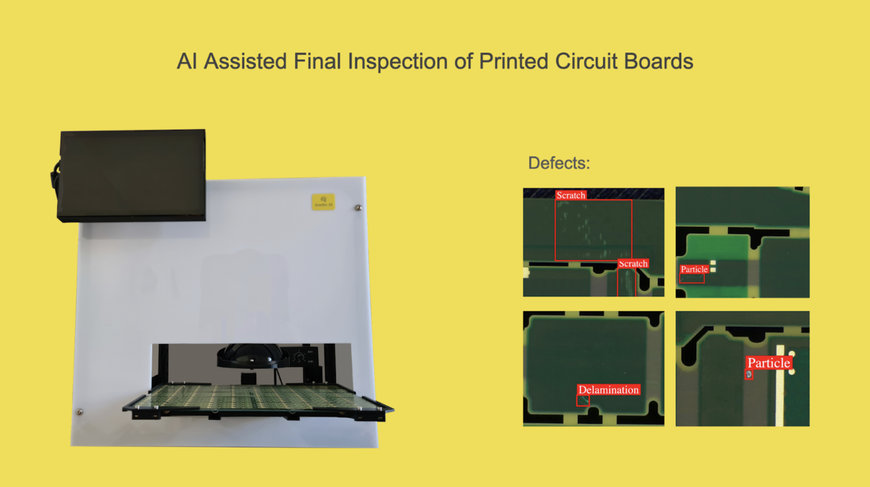

AVI is significantly different from conventional automated optical inspection (AOI) methods which normally take a PCB CAD file and compare it picture by picture. "So while existing AOI solutions work well for large batch productions, they can require significant programming effort," explains Gasimov.

"As you move forward in the production process, the variety of potential defects increases dramatically. Traditional image comparison methods struggle with issues like scratches, delamination or coating problems, which is where deep learning provides a crucial advantage."

AVI V1 needed a feature for dynamic camera lighting adjustment, critical for accurate defect detection. This came about after working on identifying defects on shiny metals that would reflect their surrounding environment, making defects hard to recognize. This solution has proved critical to the advanced detection features in the current AVI V3.

The use of AI and deep learning makes it easier to catch a wide array of novel defects inline, and at the end of line before full assembly or shipping to customers. Setting up a new inspection procedure is straightforward and doesn’t require any programming , making it particularly valuable for smaller or variable production runs.

While impressive today, the development of AVI has been iterative. The first version focused on PCB assembly inspection, later after seeing significant demand for examining bare PCBs, it was rebuilt to inspect bare PCBs themselves. This advancement has attracted attention from both PCB manufacturers and investors, leading to recent funding from the Swiss Innovation Agency through their Robotics Innovation Booster program.

While there will inevitably be growing pains as Intelec AI scales from continental Europe to the U.S., the timing is perfect as the manufacturing sector, particularly electronics, is under pressure to streamline production without compromising quality and yields. All in order to stay competitive in a global market dominated by Asia where 80 percent of PCBs are currently made.

This innovative AI-first approach for hardware has paid off, not only with existing partners.

As PCB manufacturing continues to evolve, technologies like AVI will become essential tools in maintaining quality while reducing some of the bottlenecks with classical programmatic automation and manual inspection.

The Man Behind the Machine

Some would think the company is moving quickly too with AVI V3 and the upcoming five axis microscope in R&D, but Gasimov has the character, intelligence and ambition to reach these goals. He speaks five languages including English, German and Russian. He studied at one of Azerbaijan's top engineering schools in applied mathematics (Computer Science), then when he started his career and progression seemed to stall, he went to Europe to find viable ways of reaching his lofty goals.

A master's degree in Switzerland was his first ticket to success. He enrolled at EPFL Lausanne, learning French on the side while studying his Computer Science MSc in English. Post-graduation, he landed his first job at a startup, before moving to Roche as a Data Scientist. It was there that he really began nurturing his entrepreneurial ambitions.

He started with a couple of side projects that included a salsa dancing website. Salsa is a passion of his, and where he met his wife with whom he now has three children. That project came to an end in 2017 when the Cambridge Analytica scandal broke and Facebook (Meta) cut off access to their API, and with it the live events data that the site ran on.

With this downtime between projects Gasimov began consuming Y Combinator content on entrepreneurship and completed Andrew Ng's online AI/ML course. Inspired by the transformative potential of deep learning, he built a prototype platform for training and deploying machine learning models. He saw that things had come a long way from his studies when text recognition was deemed state of the art. By 2019, he formally launched Intelec AI, transitioning to part-time work at Roche to focus on his venture.

A pivot to consultation services brought some financial success but left Gasimov yearning for a scalable product with competitive differentiation. This realization marked a critical turning point: the transition to building hardware solutions and the eventual birth of AVI (Automated Visual Inspection), which is already helping companies create far better products with less manual labor in the process.

www.intelec.ai