Benefits of Metal Oxide Varistor with a thermally coupled fuse

ThermoFuse® Varistors are used for overvoltage protection with an additional thermal element as safety feature.

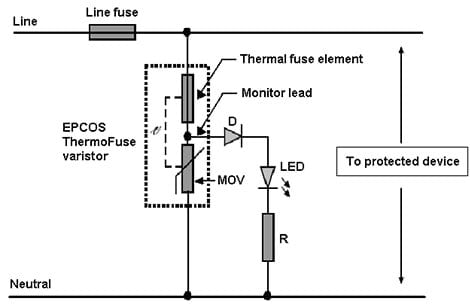

Basic example of circuit diagram for ThermoFuse® Varistor

Over the last years the fail safe functions got more popular and as a result the variety of thermally protect varistors increased on the market which resulted in many designs for different sizes and surge capabilities.

This article will show the benefits and features of TDK ThermoFuse® Varistor vs Standard Varistors.

What is the difference between a conventional varistor and a varistor with a thermally coupled fuse?

Generally Metal Oxide Varistors (varistors) are used to protect electronic devices against overvoltage surges.

However, several events can cause a thermal runaway in a varistor and the circuit protection function of the component can no longer be guaranteed.

Those events may result in the end of life of the varistor or even shortly before or if the varistor is exposeded to abnormal overvoltage conditions.

What is a varistor with thermally coupled fuse?

A ThermoFuse® varistor prevents the described failure mode with a hybrid design: it integrates a varistor and a thermo element into one component.

A disk varistor is set in series with a thermally coupled fuse. While the temperature is increasing, the thermo element starts to melt and a spring disconnects the varistor safely from the power line and avoids the reconnection.

This increases reliability and protects the equipment.

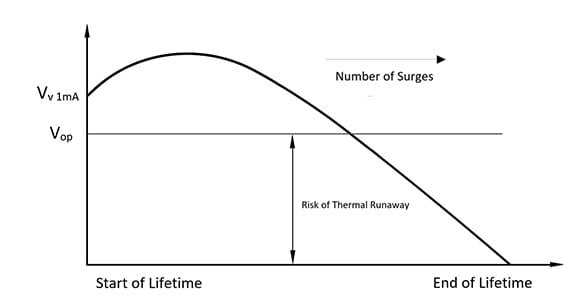

End of Life / Thermal Runaway - Varistor vs. Varistor with a thermally coupled fuse

At the start of lifetime the varistor voltage Vv is designed above the operating voltage Vop. Over time surge pulses on the load result in a drop of Vv, which might cause end of life of the varistor component and may go into thermal runaway which can result in overheating, charring, smoke and potentially fire. TDK’s ThemoFuse varistor disconnects the varistor disk from the power line when overheating, that can eliminate much of the charring and reduce the risk of fire.

Below pictures show the comparison of standard varistor and TDK NT series after abnormal overvoltage tests.

Advantages of ThermoFuse® Varistors

- Higher safety, disconnection from circuit

- High insulation and avoidance of reconnection

- Thermo element is closely connected to the varistor and can open fast during overheat event

- Reduced risk of thermal runaway and the resulting possibility of smoke or catching fire

Monitoring function

TDK ThermoFuse® Varistors are also equipped with additional indication leads which can be used to track if the component is disconnected from the power line.

The monitoring function changes the signal after a disconnection and is commonly combined with LED for a visual indication.

Why are varistors with thermally coupled fuse getting more popular?

Varistors with thermally coupled fuse are safer than single varistor components. In certain continues like fluctuation of the voltage levels or frequent surge pulses, single varistor are in risk of thermal runaway and engineers tend to use more reliable solutions like the TDK ThermoFuse® Varistors instead.

Further, additional monitoring function allows to detect the status of the component which is also getting a more popular feature. Thermofuse® varistors also fulfill higher market standards like UL 1449 Type 1-5.

Applications examples

Smart meters, Photovoltaik systems, Lighting equipement, Power supplies

www.tdk.com