Rutronik Expands Automotive Portfolio with Panasonic Metal Composite Inductors

Rutronik offers Panasonic's AEC-Q200-qualified ETQP metal composite power inductors with 170°C temperature resistance and 50 G vibration tolerance for automotive powertrain and ADAS systems.

www.rutronik.com

With Panasonic's ETQP power inductors, Rutronik offers a new generation of inductors based on metal composite materials instead of ferrite. This technology ensures high current carrying capacity, excellent heat and vibration resistance, and stable performance even under extreme conditions. The AEC-Q200-qualified inductors are ideal for automotive systems such as engine control units, pumps, brakes, and electric power steering systems. The Panasonic ETQP power inductors are available.

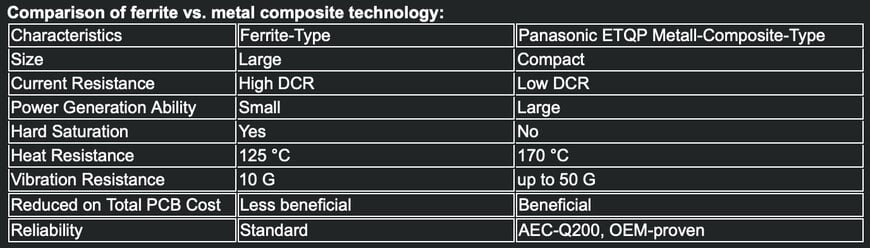

Unlike conventional ferrite types, Panasonic's ETQP power inductors use a metal composite material that offers significant advantages in current carrying capacity, saturation behavior and thermal stability: while ferrite inductors saturate quickly at high currents, the magnetization of the ETQP power inductor remains linear and temperature-stable up to 170 °C. At the same time, the material design enables more compact designs and lower power losses, which not only improves the overall efficiency of DC / DC converters but also reduces costs at the PCB level. The inductors also impress under mechanical stress: thanks to their robust construction, they can withstand vibrations of up to 50 G, making them ideal for use in safety-critical vehicle environments.

The ETQP power inductor is pin-compatible with many competing products, which facilitates integration into existing designs and ensures multi-source capability. Panasonic is the global market leader in metal composite inductors for automotive applications. With production facilities in Japan, Singapore and Indonesia, the company ensures high delivery availability and business continuity. In addition, the components score highly with zero field failures and have already been qualified by numerous global OEMs.

Benefits at a glance:

- More compact design and higher current carrying capacity

- AEC-Q200 compliant

- Temperature resistance up to 170 °C

- High vibration resistance up to 50 G

- No hard saturation, stable inductance under load

- Virtually zero field failures

- Pin-to-pin compatible with competitor products: ideal for redesigns

Application examples:

- Automotive powertrain systems: engine control units, pumps, brakes, electric power steering (EPS)

- ADAS and autonomous driving

- Automation and robotics

- Industrial electronics with high current requirements

- DC/DC converters and high-efficiency power supplies