electronics-journal.com

07

'26

Written on Modified on

High-Speed Video Links Drive Vision System Performance

Manufacturers deploy Gigabit Multimedia Serial Link technology to support high-bandwidth, low-latency video and sensor data across automotive and industrial sectors.

www.digikey.com

Gigabit Multimedia Serial Link (GMSL) technology, originally developed for automotive vision systems, is increasingly deployed in broader industrial, medical, aerospace, and transportation environments where high-resolution video and sensor data transmission are critical. Traditional interfaces such as USB or HDMI can struggle with long cable runs and electromagnetic interference in demanding settings; GMSL provides a robust alternative designed to maintain real-time performance.

The core technical challenge in these applications is the reliable transmission of large volumes of uncompressed video and control data over extended distances, often in electrically noisy conditions. Typical vision systems — delivering full-HD or higher at 60 frames per second — generate gigabits per second of data that must be carried with minimal delay and with power delivery to remote devices such as cameras or sensors.

Objectives for deploying GMSL include improving data throughput and system responsiveness, reducing wiring complexity and weight through integrated power delivery, and ensuring signal integrity across longer cable distances without resorting to compression that introduces latency.

Technical Solution

Design teams have selected GMSL as the enabling SerDes (serializer/deserializer) technology to meet these performance requirements. GMSL transmits video, control signals, and power over a single coaxial or shielded twisted-pair cable, supporting asymmetric full-duplex communication with high forward-channel bandwidth and a reverse control channel. The solution scales across three generations — GMSL1, GMSL2, and GMSL3 — with the latest versions exceeding 6 Gbps per link and supporting aggregated data flows.

GMSL’s integrated Power over Coax capability simplifies installations by eliminating separate power leads, reducing material costs and installation time. The technology also incorporates embedded clocking, enhanced electromagnetic compatibility, error correction, and diagnostic features to sustain signal integrity in harsh industrial and automotive environments where EMI and long distances challenge conventional interfaces.

System designers have favored GMSL where conventional interfaces are inadequate for real-time, multi-camera or sensor systems:

- Performance under EMI and long cable runs: In factory automation and rail transit systems, EMI can degrade standard interfaces; GMSL’s design preserves data integrity without additional shielding or repeaters.

- Bandwidth and latency: Applications requiring several gigabits per second of throughput with minimal latency — such as machine vision inspection or remote surgical imaging — benefit from GMSL’s efficient SerDes architecture.

- Reduced system complexity: The ability to carry power and bidirectional control signals over a single cable lowers cabling costs and supports modular deployment of cameras and sensors.

Backward compatibility across generations also influences adoption; designers can transition existing GMSL1 or GMSL2 installations toward higher-speed GMSL3 links without fundamentally redesigning host interfaces, mitigating risk and preserving prior investment.

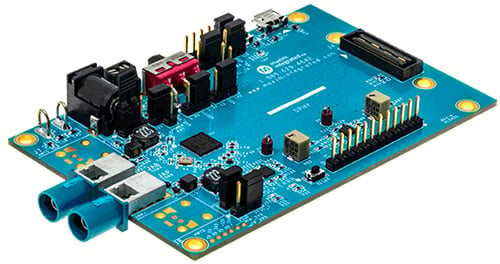

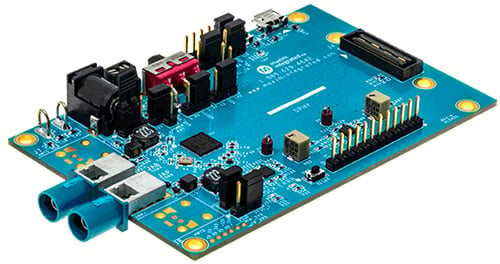

The MAX96792A-BCK-EVK# evaluation kit includes a GSML3 deserializer for prototyping applications. (Image source: Analog Devices, Inc.)

Implementations of GMSL occur at multiple levels:

The MAX96792A-BCK-EVK# evaluation kit includes a GSML3 deserializer for prototyping applications. (Image source: Analog Devices, Inc.)

Implementations of GMSL occur at multiple levels:

- Automotive ADAS and infotainment use the standard for camera and display links where real-time imaging is essential.

- Industrial and robotics vision systems connect multiple cameras to central processors via high-speed links, improving defect detection and robotic control without the latency penalties of compression.

- Medical imaging devices integrate high-resolution sensors into compact equipment where space and wiring must be minimized.

- Aerospace and rail applications employ GMSL for rugged sensor networks, benefiting from high bandwidth and system diagnostics.

Solution providers support deployment with development kits and evaluation boards to prototype GMSL links and assess performance with actual hardware before full system integration.

Quantitative performance figures specific to a single deployment are not provided in the source; however, the technical benefits are objectively discernible:

Quantitative performance figures specific to a single deployment are not provided in the source; however, the technical benefits are objectively discernible:

- Higher effective throughput than standard interfaces over extended cable lengths, enabling uncompressed high-resolution video without frame drops.

- Lower latency, which is crucial for real-time control and feedback in both automotive safety systems and automated manufacturing.

- Reduced wiring complexity and associated cost and weight savings due to integrated power delivery and combined data/control channels.

- Enhanced system resilience in environments with significant electromagnetic noise.

These combined advantages support broader adoption of GMSL beyond its automotive origins into sectors where real-time, high-bandwidth video and sensor networks are critical to operational performance.

www.digikey.com

www.digikey.com