electronics-journal.com

15

'26

Written on Modified on

Mitsubishi Electric samples new trench SiC-MOSFET bare dies

Mitsubishi Electric introduces four trench SiC-MOSFET bare dies for embedded power electronics, targeting lower losses and stable performance in EV inverters, chargers and renewable energy systems.

www.mitsubishielectric.com

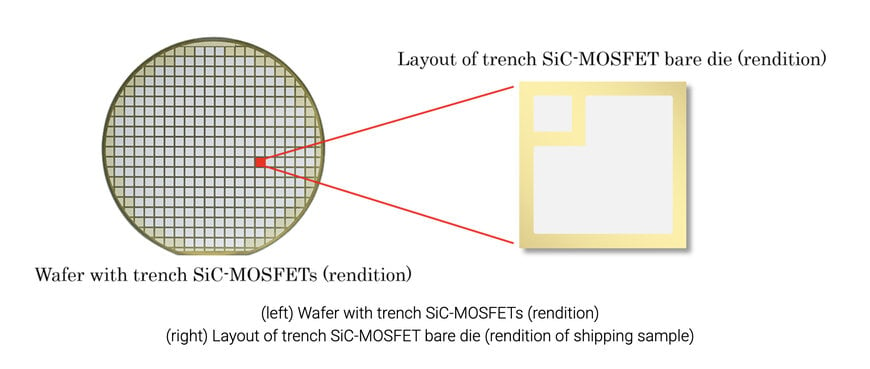

Mitsubishi Electric Corporation has announced the start of sample shipments for four new trench silicon carbide metal-oxide-semiconductor field-effect transistor (SiC-MOSFET) bare dies. The devices are intended for embedded use in power electronics equipment, including electric vehicle (EV) traction inverters, onboard chargers and power supply systems for renewable energy applications such as solar power.

Bare dies, supplied without protective packaging, enable closer integration into power modules and assemblies. This approach supports higher power density, improved thermal management and reduced electrical losses compared with fully packaged devices, making them increasingly relevant for next-generation power electronics.

Targeting efficiency and decarbonisation

Global decarbonisation efforts are driving growth in EVs and renewable energy infrastructure, increasing demand for highly efficient power semiconductors. In these applications, reducing switching and conduction losses is critical to improving system efficiency while maintaining reliability and performance.

Mitsubishi Electric has supplied silicon carbide power semiconductor modules since 2010, supporting efficiency gains in air conditioning systems, industrial equipment and railway traction inverters. The newly introduced bare dies extend this portfolio to address growing demand for embedded semiconductor solutions.

Trench SiC-MOSFET structure

The four new devices are based on Mitsubishi Electric’s proprietary trench SiC-MOSFET architecture. Compared with conventional planar SiC-MOSFET designs, the trench structure reduces power loss by approximately 50%, enabling lower energy consumption at the system level.

In addition, proprietary manufacturing processes, including a dedicated gate oxide film formation method, are used to minimise variations in on-resistance and power loss. This process control is intended to support stable electrical characteristics and long-term reliability during extended operation.

Application scope

The new bare dies are designed for integration into power electronics used in EV drivetrains, onboard charging systems and renewable energy power supplies. Their form factor allows equipment manufacturers to optimise layouts for compactness and thermal performance while maintaining high efficiency.

By supporting diverse embedding requirements, the devices enable greater flexibility in module and system design across automotive and energy sectors.

Industry presentation

Mitsubishi Electric will showcase the new trench SiC-MOSFET bare dies at the NEPCON Japan R&D and Manufacturing Show, taking place in Tokyo from January 21 to 23. The company also plans to present the devices at exhibitions across North America, Europe, China, India and other regions.

With the introduction of these new SiC-MOSFET bare dies, Mitsubishi Electric expands its silicon carbide portfolio to support higher efficiency, lower power consumption and advanced integration strategies in next-generation power electronics systems.

www.mitsubishielectric.com