electronics-journal.com

22

'26

Written on Modified on

Schmalz develops ESD-safe suction cup material for electronics handling

The new material targets electronics manufacturing, combining ESD protection, low marking behavior, and thermal resistance for automated handling of sensitive components.

www.schmalz.com

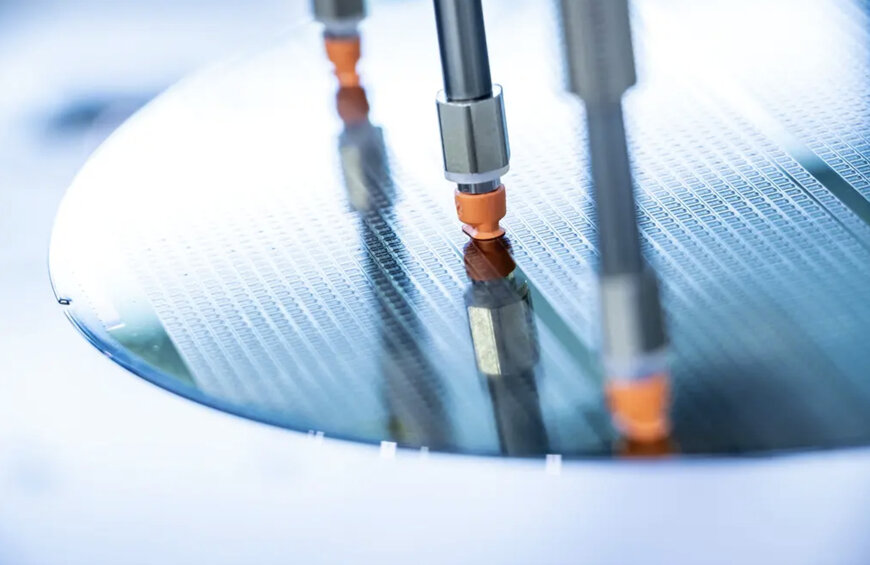

Schmalz has introduced HT1-ESD, a new suction cup material designed to address multiple handling challenges in electronics production, including electrostatic discharge protection, surface cleanliness, and thermal stability.

In electronics manufacturing, even minor surface residues, particle contamination, or uncontrolled electrostatic discharge can lead to yield losses, functional defects, or costly rework. Conventional suction cup materials often require trade-offs between ESD protection, marking behavior, durability, and temperature resistance. HT1-ESD combines these requirements in a single material system.

The material integrates the low-residue characteristics of HT1 with the electrostatic discharge properties of NBR-ESD. As a result, suction cups leave minimal chemical traces on sensitive surfaces such as semiconductor wafers and electronic housings, reducing the risk of visible marks or contamination. At the same time, the material provides reliable ESD protection without relying on external coatings or conductive carbon black additives.

By avoiding conductive fillers that can detach over time, HT1-ESD reduces particle generation and maintains consistent ESD performance throughout its service life. This contributes to cleaner processes, lower maintenance effort, and improved machine availability in automated production environments.

HT1-ESD withstands operating temperatures of up to 170 °C while maintaining its mechanical and chemical properties. High resistance to ozone and wear further extends service life, supporting stable operation in high-cycle pick-and-place applications.

Suction cups made from HT1-ESD are intended for use across a wide range of electronics manufacturing processes, including semiconductor production, consumer electronics assembly, and household appliance manufacturing. Schmalz supplies the material in multiple suction cup geometries to accommodate different component shapes and handling requirements.

www.schmalz.com