TDK releases new stray-field robust 3D HAL® position sensor with SPC interface

TDK Corporation (TSE:6762) announces the portfolio expansion of the Micronas masterHAL® sensor family with the release of HAL 3970, a new stray-field robust 3D HAL® position sensor.

- 3D position sensor with SPC interface based on the Hall-effect allows active stray-field compensation

- 360 degrees, stray-field robust angular measurement makes this sensor suitable for steering-angle position detection*

The sensor, suited for automotive and industrial applications, has highly accurate angular detection from 0° to 360°, linear position detection, and uses Short PWM Code frames (SPC) to transmit the calculated position information. SPC is an enhancement of the standard SENT protocol according to SAE J2716. It enables data to be transmitted based on a trigger pulse sent by an external ECU, and it supports point-to-point connections as well as a single-wire bus mode with up to four sensors. Parameters such as unit time, frame format, trigger mode, slow channel format, rolling counter, and more, are easily configurable. For example, HAL 3970 can be used for stray-field robust angle detection in steering-wheel position applications*. Samples will be available in the fourth quarter of 2020.

Each sensor within the HAL 39xy sensor family is based on the patented 3D HAL pixel cell technology**. HAL 3970 uses a special array of Hall plates for high-accuracy measurement of vertical and horizontal magnetic-field components. Due to the sophisticated arrangement of these Hall plates, the sensor detects angles up to 360 degrees and suppresses external magnetic stray fields. Only a simple two-pole magnet is required to determine rotation angle. Ideally, the magnet should be placed above the sensitive area in an end-of-shaft configuration. The sensor also supports stray-field robust off-axis measurements.

The on-chip signal processing of HAL 3970 calculates the angle out of the magnetic-field components and converts this value into a digital output value. The sensor features a powerful DSP and an embedded microcontroller. The DSP is responsible for fast signal processing, while the microcontroller performs the interface configuration and supervision of the functional safety-related tasks.

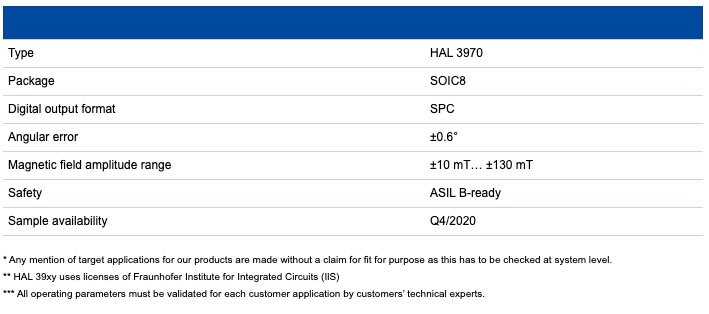

Primary characteristics like gain and offset, reference position, etc. can be adjusted to the magnetic circuitry by programming the non-volatile memory. HAL 3970 is defined as SEooC (Safety Element out of Context) ASIL B-ready, according to ISO 26262. HAL 3970 is available in the eight-pin SOIC8 SMD package.

Glossary

3D HAL® pixel cell: Enables the direct measurement of magnetic fields in three directions X, Y, Z.

Stray-field compensation: Modern Hall-effect sensors must be insensitive against disturbing fields generated by e-motors or power lines in hybrid (xHEV) or electrical vehicles (xEV).

Main applications*

- Steering-angle detection

- Long-stroke measurements in transmission systems or clutch applications

Main features and benefits***

- Stray-field robust position detection (linear and rotary up to 360°) covering ISO 11452-8 requirements

- Compensation of stray fields with gradients for applications with 180° rotation

- Transmission of position and temperature information including rolling counter

- Supports SPC-enhanced 12-bit serial message format including temperature information

- Various SPC trigger modes (constant/variable length and short trigger pulse (point-2-point))

- Programming via sensor's output pin at minimum supply voltage

- SEooC ASIL B-ready according to ISO 26262 to support functional safety applications

- Wide supply voltage range: 3.0 V to 16 V

- Up to 16 kSps sampling frequency

- Suitable for automotive applications due to a wide ambient temperature range from -40 °C up to 150 °C

Key data

www.tdk.com