electronics-journal.com

18

'25

Written on Modified on

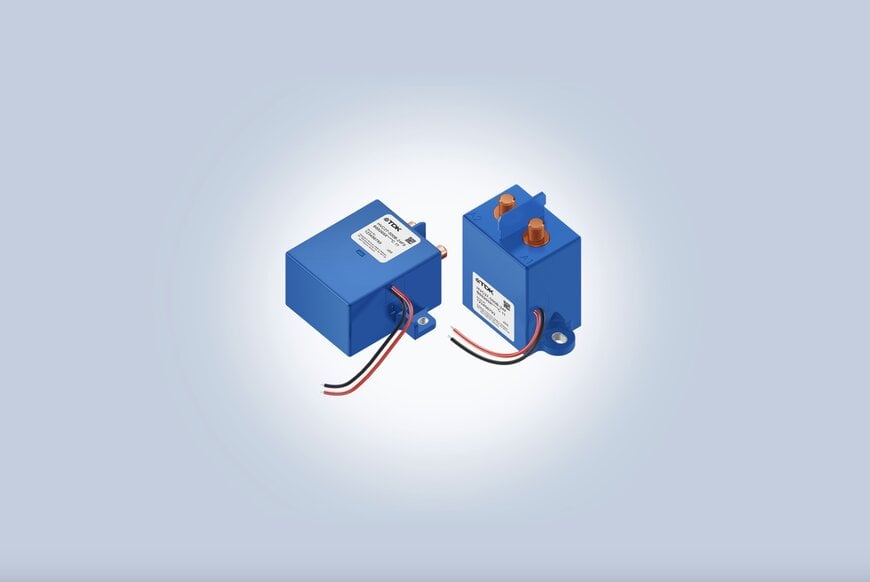

High-Voltage DC Contactors with Mirror Contacts

TDK expands its high-voltage switching portfolio with compact DC contactors designed to provide safety-relevant feedback in electric mobility and industrial energy systems.

www.tdk.com

TDK Corporation has introduced the HVC27*MC series of high-voltage DC contactors, integrating a mechanically linked mirror contact to support functional safety requirements in battery, energy storage, and high-power DC applications.

Safety-relevant contact feedback for high-voltage systems

The HVC27*MC series adds a normally closed auxiliary contact that is mechanically linked to the main power contacts and compliant with IEC 60947-4-1. This mirror contact provides direct feedback on the actual contact position, enabling control systems to detect welding, incomplete opening, or other switching anomalies.

Such feedback is increasingly required in safety-critical architectures, particularly in battery disconnect units and energy systems where incorrect contact states can lead to hazardous conditions. By reporting the real mechanical status of the power contacts rather than relying solely on control signals, the mirror contact supports higher diagnostic coverage in functional safety concepts.

Electrical ratings and switching performance

The contactors are designed for DC systems up to 1000 V and are available in continuous current ratings of 300 A, 400 A, and 500 A. In addition, the devices support a single-shot current capability of up to 900 A at 1000 V for durations below 20 ms, covering short-term overload or fault scenarios.

The main power terminals are fully bidirectional and polarity-free, simplifying integration into different system topologies without requiring orientation-specific wiring.

Arc management and interruption reliability

To ensure safe interruption of high DC currents, the HVC27*MC series uses a hermetically sealed, gas-filled ceramic arc chamber. This design controls arc energy during opening and prevents external contamination, supporting consistent switching behavior over the service life.

Gas-filled contactors are commonly used in high-voltage DC applications where arc suppression is more challenging than in AC systems due to the absence of natural current zero crossings.

Compact form factor for space-constrained designs

Despite its electrical ratings, the contactor maintains a compact footprint of 86.5 × 95 × 44 mm and a weight of approximately 530 g. This size and weight profile supports integration into dense battery packs, power electronics cabinets, and modular energy systems where space efficiency directly affects overall system design.

The combination of high current capability and compact dimensions allows designers to reduce enclosure size or increase functional density within existing layouts.

Deployment readiness and environmental robustness

The HVC27*MC series is offered with 12 V or 24 V coil voltages and carries UL, CE, and UKCA certifications, enabling deployment across global markets. The mechanical design is qualified for demanding vibration and shock environments, supporting use in commercial vehicles, industrial machinery, and stationary high-voltage installations.

Such robustness is essential in applications where contactors are exposed to continuous mechanical stress, including mobile energy systems and electrified transport platforms.

Application context in electric mobility and energy systems

Typical application areas include battery disconnect units in electric vehicles, energy storage systems, DC fast charging infrastructure, and uninterruptible power supplies. In these systems, reliable isolation and accurate state feedback are central to meeting regulatory, safety, and operational requirements.

By integrating mirror contact functionality into a compact high-voltage DC contactor, the HVC27*MC series addresses a growing need for verifiable switching states within modern electric power architectures, supporting safer system operation without increasing design complexity.

www.tdk-electronics.tdk.com