electronics-journal.com

27

'21

Written on Modified on

KEMET Introduces High Temperature, Power DC-Link Film Capacitor for Extended Lifetime Requirements in Automotive and Green Energy Applications

Smoothing film capacitor offers high temperature and high capacitance density for EVs and green energy power electronics that require high heat resistance and safety.

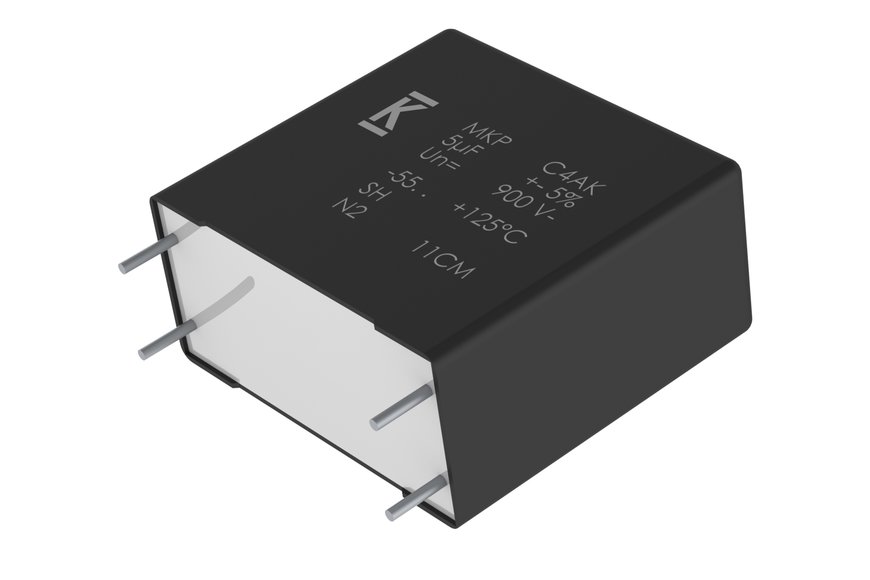

KEMET, part of the YAGEO Group and leading global electronic components supplier, announces its new C4AK high temperature, power film DC-Link capacitor designed for continuous operation up to 1,000 hours at 135℃. The C4AK series joins the C4AU (harsh environment) and C4AQ-P (125°C) family of power DC-Link film capacitors.

These series offer higher capacitance density, DC voltage, and DC ripple current capabilities with an extended operational lifetime at high temperatures in harsh environments. Ideal for use in automotive, green, and industrial applications, these metallized film capacitors are well suited for DC filtering and DC-Link in solar, fuel cells, inverters, storage energy systems, automotive (Bi) On-Board Charger, Wireless Power Transfer (WPT), DC/DC, heaters, and welding equipment.

Growing demand for electric vehicles, base stations, and technological advancement in charging stations powered by renewable energy require electronic components that are compact, lightweight, and have high dielectric capacitance coupled with high heat resistance for extended operational profiles. Additionally, capacitors used in converter and motor drive inverters require greater assurance of high-temperature performance than ever before. This new series launches at a time when electric automotive technologies are growing at a rapid pace. According to the Precedence Research report, the global electric vehicle market is expected to reach a compound annual growth rate (CAGR) of 40.7% from 2020 to 2027.*

Due to its enhanced performance design, the KEMET DC-Link C4AK film capacitor provides a superior alternative for current capacitor solutions. Design features include a radial box style for PCB mounting, miniaturization, low profile, 2 – 4 leads, and fewer capacitors needed in parallel to meet the required peak and ripple current.

The C4AK film capacitor surpasses the extreme conditions of the standard automotive (AEC-Q200) requirements for film technology in severe humidity/temperature conditions. Compared to competitor technologies, the C4AK series has greater performance with a lifetime of 4,000 hours at 125°C and 1000 hours at 135°C in harsh environmental conditions. The C4AK DC-Link film capacitor's extended life at high temperatures provides designers an ideal miniaturized, reduced component count solution over conventional film capacitors, particularly in Wide Band Gap high frequency, high current systems.

www.kemet.com