Boron Nitride Cooling Fillers from 3M Used for Thermal Management in Advanced Polymers

Enhanced performance, reliability and energy savings in your automotive, electrical and electronic components.

3M (NYSE: MMM), a leader in high-performance polymer additives, has expanded their line of boron nitride cooling fillers applicable to a wide array of automotive, electrical and electronic devices and components.

The new grades from 3M are:

- Boron Nitride Cooling Filler Agglomerates CFA 100

- Boron Nitride Cooling Filler Agglomerates CFA 150

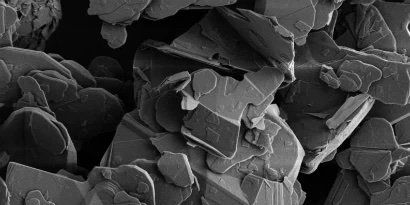

Both consist of soft boron nitride agglomerates used to enhance isotropic thermal conductivity. They provide better through-plane conductivity than platelets or flakes, and their softness helps facilitate low impact on viscosity and easy processing that is less abrasive on equipment.

Boron nitride cooling filler agglomerates from 3M can be added to potting resins, conformable TIM foils or pads and other applications where isotropic thermal conductivity is important. They are also used for bond lines of 150–200 µm (100 grade) and 200 µm or above (150 grade).

Background

To maintain long-term reliability and efficiency, many modern devices require advanced materials to transfer excess heat and dissipate it to the surrounding air. Examples include laptops and smartphones as well as high-capacity batteries and motors used in electric/hybrid vehicles.

From phones to automobiles, more and more products are incorporating 5G components, requiring more electronics, which in turn generate more heat. For resin suppliers, compounders and component manufacturers, the challenge of thermal management has never been greater.

About Boron Nitride Cooling Fillers from 3M

3M designed its boron nitride cooling fillers to address this challenge. Boron nitride is a material consisting of boron and nitrogen well-known among chemists for its thermal stability and conductivity.

3M utilizes these properties to produce a family of lightweight ceramic fillers that, when added to polymer compounds, enhance thermal conductivity while maintaining or improving electrical insulation. Boron nitride cooling fillers from 3M can achieve high heat removal while also solving electrical insulation, viscosity and dielectric property requirements. The multifunctioning properties of boron nitride as a filler can also help eliminate the need for metal heat sinks and additional insulation layers, helping you reduce component size, weight and system cost.

With boron nitride cooling fillers, small plastic components—including those with complex geometries—can dissipate heat effectively and achieve long-term reliability and performance. These fillers from 3M facilitate a range of thermal conductivity from 1 to 15 W/m·K depending on the materials and application requirements.

Boron nitride cooling fillers can be added to thermoplastics, elastomers, thermosets and more. They are gentle on tooling and can be safely used in compounding, extrusion and injection molding processes.

www.3m.com