electronics-journal.com

21

'21

Written on Modified on

Nicomatic’s custom interconnect solutions solve customer design challenges to deliver innovative systems with competitive edge

Nicomatic engineers co-design with customers; as one-source supplier can incorporate other manufacturers’ devices; full custom design to production typically 12 weeks; no minimum order required.

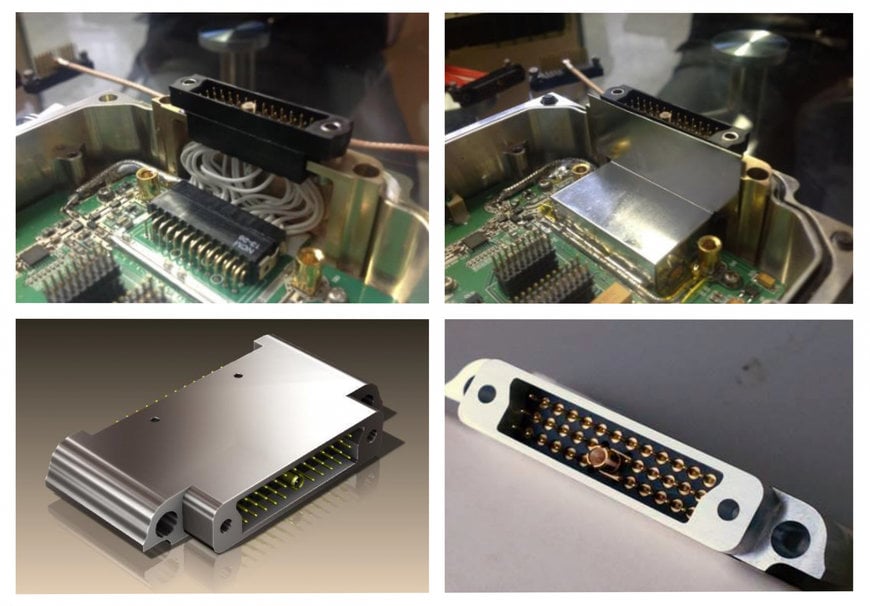

incorporated an EMI backshell, saved significant PCB space and required no harness.

Nicomatic, the leading manufacturer of high performance interconnect systems, is seeing increased sales of its custom interconnect solutions as its customers recognise that a custom solution can deliver optimised systems that incorporate additional functions and give their product an edge in competitive markets.

With its established reputation as a manufacturer of ruggedized custom solutions, as well as the extreme flexibility of its standard connector ranges enabled by Nicomatic’s modular manufacturing capabilities, the company is capitalising on its expertise in its key markets of medical, rail, aerospace and defence to deliver an enhanced custom solution design and manufacture service to clients that is second-to-none. Nicomatic handles over 1,000 custom design quotes a year and this was maintained even during the challenging conditions of the past 18 months.

The company’s approach to delivering a full-service custom solution is simple – potential customers with a challenging design can meet with a local Nicomatic Engineer to discuss the requirement who will work with them, suggesting solutions the customer may not have thought of. It is also possible to send Nicomatic Sales Engineers and Field Applications Engineers a sketch or description of the requirements, plus three must-have features, and within a maximum of 72 hours receive an expert view on the feasibility of the project.

Nicomatic’s manufacturing is optimised for modularity and custom designs, with the ability to machine parts quickly for prototype devices and make moulds at the same time ready for a switch to moulded parts when high volume production is needed. From design start to delivery of a full custom solution takes as little as 12 weeks. For simple customisation projects, three weeks is usual. With engineers located in France, the UK, Asia and N. America, the Nicomatic custom service is global.

Phil McDavitt, MD, Nicomatic Ltd. comments: ”The advantages of Nicomatic’s custom solution include not only solving a design problem, but delivering a unique solution that makes the customer’s design exclusive and keeps it ahead of competitors. The perception that custom design is expensive is also a myth when the total cost of trying to make standard parts fit is considered – there are hidden costs and hidden time involved in that approach. We can now also have our engineers work within customer teams if required to co-design with them, which is new and exciting.”

A new page on Nicomatic’s custom design and manufacturing capabilities is available at:

https://www.nicomatic.com/family/285

www.nicomatic.com