electronics-journal.com

28

'22

Written on Modified on

Space-Saving Schottky Rectifiers from Diodes Incorporated Set New Benchmarks in Current Density

Diodes Incorporated (Diodes) (Nasdaq: DIOD) has announced the introduction of a series of high-current Schottky rectifiers in ultra-compact chip scale packages (CSPs).

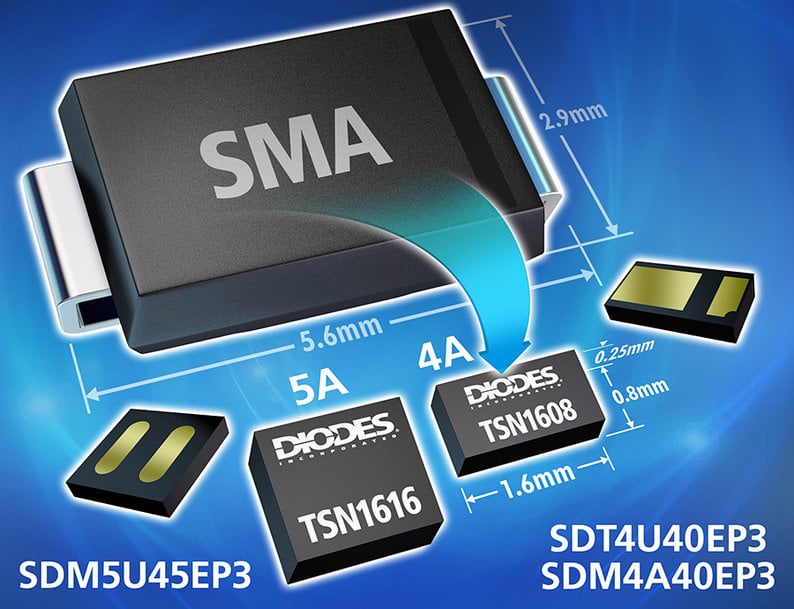

The DIODES™ SDM5U45EP3 (5A, 45V), DIODES™ SDM4A40EP3 (4A, 40V), and DIODES™ SDT4U40EP3 (4A, 40V) achieve the industry’s highest current densities in their class, addressing market demands for smaller and more powerful electronic systems.

Each device can be employed for a variety of different purposes, serving as blocking or reverse-polarity protection diodes, electrical over-stress protection diodes, and free-wheeling diodes. The rectifiers in this series are designed for use in space-constrained applications - such as portable, mobile, and wearable devices, as well as IoT hardware.

Leading the trio, the SDT4U40EP3 is the industry’s smallest 4A trench Schottky rectifier, being the first ever in a 1608 package. It takes 90% less PCB area than competing devices. Its 800A/cm2 current density, also the highest for a trench Schottky in the industry, is due to its patent-pending innovative cathode design and manufacturing processes. The resulting ultra-low forward voltage performance (0.47V typical) minimizes power losses, enabling the design of higher efficiency systems. Furthermore, its superior avalanche capability makes it robust enough to deal with extreme operating conditions, including transient voltages.

The X3-TSN1616-2 packaged SDM5U45EP3 has a 2mm2 footprint, while the 1.28mm2 footprint of the X3-TSN1608-2 packaged SDM4A40EP3 and SDT4U40EP3 enable system designers to maximize board real estate in modern, highly integrated consumer products. These ultra-thin CSPs, with their 0.25mm (typical) profiles, have shortened thermal paths - resulting in greater power dissipation, reducing thermal BOM costs and increasing reliability.

Advance samples are available upon request from: www.diodes.com/about/contact-us/sales-support/

www.diodes.com