electronics-journal.com

03

'24

Written on Modified on

TTI Europe introduces Murata’s compact safety certified MLCCs for fast charging EVs

Advanced moulding capabilities extend the creepage distance required for 800V battery architectures.

Europe, a leading specialty distributor of electronic components, announces the introduction of a new range of multi-layer ceramic capacitors (MLCCs) from Murata. The EVA series possesses qualities that will be particularly desirable to engineers developing next-generation electric vehicles (EVs). Automotive powertrain applications include the on-board charger (OBC), battery management system (BMS), and inverters and DC-DC converters, as well as other industrial, consumer and medical implementations.

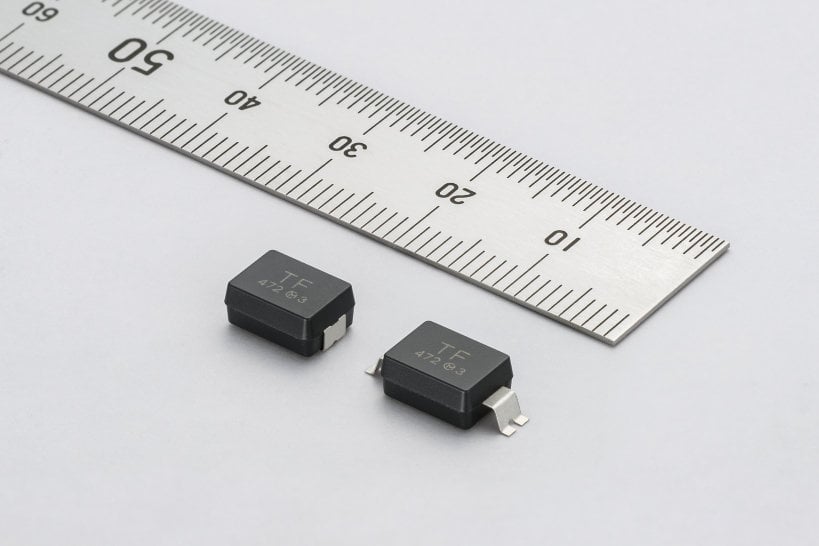

Developed in accordance with IEC60384-14 safety standards, the safety-certified Y2 class MLCCs are particularly effective at suppressing common mode noise. Housed in surface mount packages, with a 12.7mm x 6mm footprint and 3.7mm profile, these compact parts offer 305Vac/1500Vdc voltage ratings and support 10mm creepage distances. As a result, they can satisfy the increased isolation required by the industry’s migration to 800V powertrains for faster charging capabilities, while simultaneously remaining consistent with the demand for miniaturization and weight reduction.

The EVA series offers capacitance values ranging from 0.1nF to 4.7nF and, with an extended -55°C to +125°C operating temperature range, is AEC-Q200 qualified. Providing a greater safety margin, the MLCCs are tested to elevated withstand voltages of 2000VAC/60s and 4000VDC/60s to accommodate transient overvoltages, such as voltage surges and switching transients. In addition, the parts exhibit low equivalent series inductance (ESL), making them suitable for use at high frequencies. The metal terminal arrangement of these MLCCs provides greater elasticity, mitigating the formation of solder and deflection cracks, thereby assuring long-term reliability.

“As EV powertrains move to higher voltages, longer creepage distances are now being mandated for use in automotive powertrains. At the same time, these parts must take up less physical space,” explains Felix Corbett, Director of Supplier Marketing, Passives and Discrete Components, TTI, Inc. – Europe. “Drawing on Murata’s advanced resin molding capabilities, the EVA series of MLCCs exceeds these requirements, combining extended creepage with compactness.”

In addition to technical support, TTI can provide product samples for design and prototyping. The company’s local and regional logistics support program also supports all required inventory levels through to production. For more information about the EVA series of automotive safety MLCCs, please visit.

www.ttieurope.com