electronics-journal.com

14

'25

Written on Modified on

Würth Electronics ICs Showcase Innovations at PCIM 2025

Discover Würth Electronics' latest power IC advancements, featuring cutting-edge efficiency, compact designs, and next-gen solutions for industrial and automotive applications.

www.we-online.com

Würth Elektronik ICS will be exhibiting at PCIM in Nuremberg from 6 to 8 May 2025. The specialist for PCB connection solutions in the high-current sector and inventor of Powerelements will be focussing on power electronics at exhibition stand 337 in hall A6. Taking centre stage: the lead-free Powerelement ‘LF PowerBasket’, an innovative pluggable high-current contact for contacting printed circuit boards in demanding industrial and automotive applications.

The LF PowerBasket can be connected to the PCB using press-fit technology, SMT or THT. Thanks to a special contact alloy, the LF PowerBasket can be used at a continuous operating temperature of 150 °C. The contact springs of the LF PowerBasket form a basket that is optimally designed to hold the contact pins and blades with low insertion forces. This basket design of the LF PowerBasket without a plastic housing is characterised by a high position tolerance of 0.6 mm. The Powerelement can therefore be used very well for board-to-board connections with multiple contacts. Additional advantages of the pluggable connections include reduced installation effort and simplified maintenance procedures. A 3D-printed oversized version of the LF PowerBasket SMD will provide entertainment at the trade fair stand, where visitors can prove their marksmanship in a basketball game.

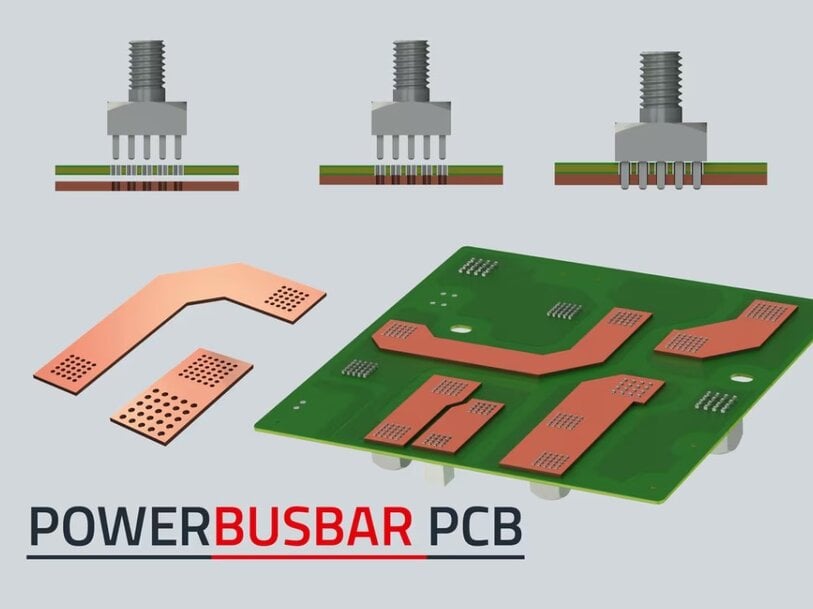

PowerBusbar PCB

The PowerBusbar PCB busbars are another highlight at the exhibition stand. These copper busbars are ideal for the systematic distribution of high currents to PCBs. In combination with Powerelements such as LF PowerOne Press-Fit and LF PowerPlus, they are pressed together with the PCB in a single operation. The solid press-fit technology creates a gas-tight cold-welded connection with low contact resistance, which guarantees a very high current-carrying capacity. The busbar design is customised based on the PCB layout, ensuring optimum adaptation to the respective application. Offering a wide range of design options, the busbars are typically manufactured in thicknesses of 1.0 or 1.5 mm.

www.we-online.com