Reed Relays Prove Critical for Precision Semiconductor Testing, Reveals Pickering Guide

Pickering Electronics’ expert guide outlines how reed relays optimize semiconductor wafer testing, offering reliability and precision for ATE systems in parametric and functional validation.

www.pickeringrelay.com

Pickering Electronics has announced availability of another in its series of educational application guides for engineers building ATE (automatic test equipment) and test & measurement (T&M) systems, titled: ‘5 Reasons Why Reed Relays are Ideal for Semiconductor Testing’. This expert-authored comprehensive application guide explains more about the critical role of reed relays in semiconductor test, particularly during wafer probe testing. The guide provides insights on using reed relays in semiconductor ATE applications, including Pickering’s top five reasons why reed relays are the ideal switching technology for semiconductor test.

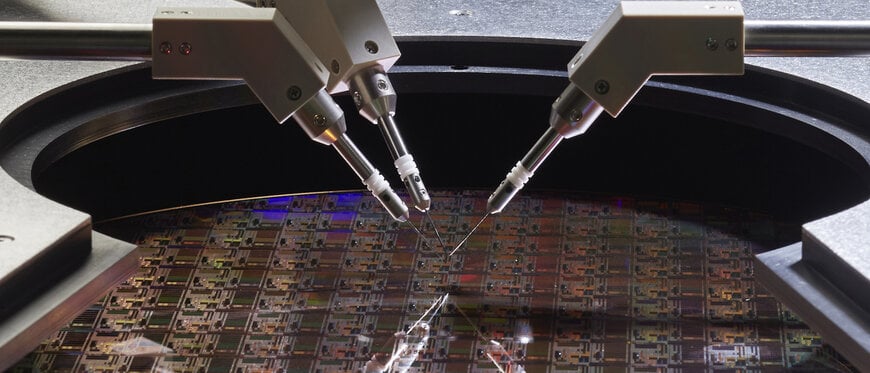

After semiconductor wafers are fabricated, but before they are ‘sliced and diced’ into the dies that will be packaged into components, they are subjected to wafer probe testing. These critical electrical and functional tests are performed by wafer probing machines, a type of automatic testing equipment (ATE) that is used to verify the functionality of the individual dies – be they relatively simple structures, such as diodes and transistors, or more complex integrated circuits (ICs), such as processors, microcontrollers, memory, and analogue to digital converters (ADCs). Such testing helps identify any defects early, confirm functionality, and ensure the quality of dies before they are packaged and used in electronic devices, helping improve yield.

The probes are moved around the wafer to connect with pads on the surface of individual dies and to apply test conditions (voltages, currents, or waveforms, for example) that the ATE supplies – as well as measure voltage levels, current flow, or output waveforms, for example, that the ATE needs to record. Semiconductor test methods include DC parametric testing (at different levels of current and voltage) and AC parametric testing (at different frequencies) – both to ensure the device meets the required specifications – and functional testing to ensure that it operates as intended. For power semiconductor devices, it is necessary to apply and record high voltages, and for high/radio frequency (HF/RF) devices, it is necessary to apply and record appropriate waveforms.

“All of this means that the ATE must be capable of applying a variety of test conditions,” explains Robert King, Reed Relays Product Manager at Pickering Electronics. “However, probe stations typically have only a few probes (just two is fairly standard), so the ATE must be able to switch between multiple test conditions and channel the test results into the appropriate signal conditioning circuitry – and this is where reed relays, as controllable switching devices, prove invaluable. Pickering’s application guide explains the top five reasons why reed relays are the ideal switching technology for semiconductor test.”

Download the free guide today to reveal Pickering's expert insights and recommendations on selecting the right relay technologies for your specific needs – and discover why reed relays are the idyllic switching technology for semiconductor test.

Pickering reed relays are known for their reliability due to superior manufacturing and quality control processes. They feature instrumentation-grade sputtered ruthenium contacts, rather than the more common electroplated rhodium associated with low grade reed relays with less stable contact resistance. Along with Pickering’s formerless coil construction, this maximises magnetic efficiency, enabling the use of less sensitive reed switches, resulting in optimal switching action and extended lifetime at operational extremes. Magnetic mu-metal screening eliminates problems that would otherwise be experienced due to magnetic interaction when relays are closely stacked. Read more about the top 10 key benefits of using Pickering relays over other typical industry relays.

www.pickeringrelay.com