ROHM Launches 4th Gen SiC MOSFETs at Rutronik

ROHM’s Gen 4 SiC MOSFETs at Rutronik deliver low on-resistance, reduced switching loss, and 175 °C reliability with integrated drivers and evaluation boards.

www.rutronik.com

Rutronik introduces the new 4th Gen N-Channel SiC power MOSFETs from ROHM. The power switching devices offer low switch-on resistance with improved short-circuit resistance, minimize switching losses by drastically reducing the gate-drain capacitance, and support the 15 V gate-source voltage for even more energy savings and design freedom. Thanks to their high robustness, they are predestined for use in electric vehicles, industrial drives, and aerospace applications, among others. The MOSFETs are available together with the corresponding modules and drivers as well as the half-bridge evaluation boards, which support integration into customer applications.

ROHM has the entire manufacturing know-how for SiC MOSFETs, provides substrate, wafer, packaging, and testing from a single source and, in addition to the discrete SiC MOSFETs, also offers corresponding modules and driver components as well as half-bridge evaluation boards.

The P04SCT4018KE-EVK-001 and P05SCT4018KR-EVK-001 half-bridge evaluation boards were developed for Gen 4 SiC MOSFETs in compact TO-247N and TO-247-4L housings and support the rapid implementation of new applications during development. Integrated gate drivers and peripheral circuits reduce the workload for design and evaluation.

The HB2637L-EVK-301 evaluation board enables evaluations in operating modes such as downward, upward, synchronous downward/upward, and inverter operation. It integrates two SiC MOSFETs, an isolated gate driver including power supply, a low dropout regulator (LDO) for a 5 V supply, and easy-to-connect ports for pulse width modulation signals (PWM).

The BM61M41RFV-C gate driver has an isolation voltage of 3,750 Vrms, an I/O delay time of just 65 ns and a minimum input pulse width of 60 ns. It is galvanically isolated and equipped with Under-Voltage-Lockout (UVLO), and the Miller clamping function. The component is AEC-Q100 qualified and UL1577 recognized.

The SiC MOSFETs benefit from the improvement of the component structure based on the original double-trench design. Thus, it achieves up to 40 % lower on-resistance with significantly higher robustness compared to similar components. By drastically reducing parasitic effects such as the gate-drain capacitance, switching losses are reduced by up to 50 %.

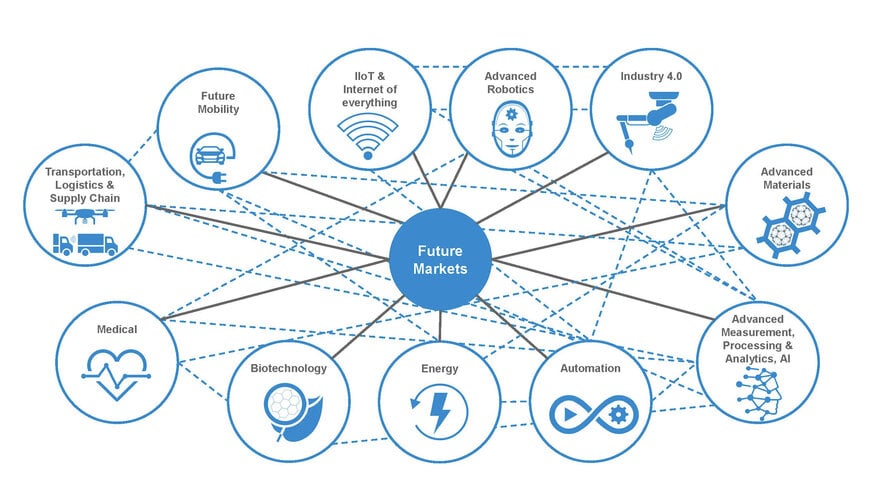

In contrast to the third generation SiC MOSFETs, the fourth generation supports a more flexible gate voltage range of 15 V to 18 V. This enables the development of a gate driver circuit that can also be used for insulated-gate bipolar transistors (IGBT) at high currents. The components can withstand a thermal load of up to +175 °C, and can be easily connected and controlled in parallel. They are lead-free and RoHS-compliant and ideal for use in automotive, industrial, or new energy applications, as well as in all future markets.

Benefits at a glance:

- High short-circuit resistance

- Minimized switching loss

- Supports 15 V - 18 V gate-source voltage

- Reliable performance at temperatures up to +175 °C

Application examples:

- Electric vehicles

- Chargers and DC / DC converters

- Photovoltaic inverters

- Industrial drives

- Aerospace technology

For more information to the 4th Gen Sic MOSFETs.

www.rutronik.com