electronics-journal.com

15

'25

Written on Modified on

New Tool for Next-Generation Microdisplays

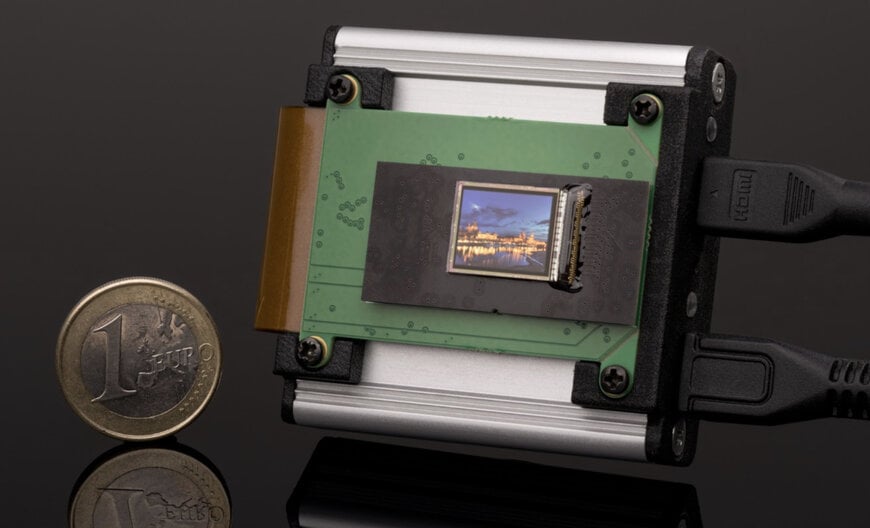

Fraunhofer IPMS unveils a new EdgeVision Microdisplay technology improving efficiency and quality in high-resolution microdisplay production, with results showcased at the SID-MEC Conference, from November 3 to 4, 2025, in Göttingen.

www.fraunhofer.de

Microdisplays are used in a variety of applications ranging from consumer electronics to specialized industrial sectors. Here are some of the key areas of use:

- Augmented Reality (AR) and Virtual Reality (VR): Enabling immersive experiences in headsets.

- Wearable Technologies: Compact and energy-efficient displays in glasses, smartwatches, and fitness trackers.

- Medical Devices: High-resolution image displays in endoscopes and diagnostic instruments.

- Industrial Applications: Important information in head-up displays (HUDs) for vehicles.

- Cameras and Projectors: Compact solutions for digital image representation.

- Defense and Aerospace: Displaying critical information in cockpits and helmets.

Due to their versatility and compact design, microdisplays are a central component of modern technologies, enabling innovative solutions across various industries, and the market is growing rapidly.

The Fraunhofer IPMS is considered the only independent research and development center worldwide for microdisplay technologies, which also integrates backplane IC design in silicon foundry processes and OLED-on-silicon manufacturing technology under one roof. This allows the institute to develop and manufacture customer- and application-specific OLED microdisplays. However, scientists are also developing backplanes for other display technologies, such as micro-LED and LCOS (liquid crystal on silicon).

To continue being a leading provider of technology developments, the institute has now expanded and renewed its plant technology. This innovative technology promises a significant improvement in the efficiency and quality of manufacturing high-resolution microdisplays.

The new tools enable the thermal deposition of complex organic stacks, metal layers, and oxides, facilitating the development and manufacture of high-resolution OLED microdisplays as well as sensors such as organic photodiodes.

“With the new equipment, we can thermally deposit complex organic stacks, metal layers, and oxides that enable us to develop and manufacture ultra-high-resolution OLED microdisplays, as well as sensors such as organic photodiodes,” explains Bernd Richter, head of microdisplay and sensor technology at Fraunhofer IPMS. “The industry-compatible systems are state-of-the-art and can be flexibly combined to meet the high demands of research and development projects while also providing high efficiency for pilot production.”

Specifically, the new technology achieves higher throughput, and significantly improved process control leads to stable manufacturing processes. The new etching chamber of the system can perform various pretreatments of wafers from different suppliers.

The greatest challenge in this context was to couple the new vacuum system components with the existing plant technology.

The scientists are confident that they can remain competitive and offer their customers a unique portfolio: from the design of microdisplays to the production of initial prototypes to pilot manufacturing from a single source.

The acceptance of the new system is planned for the end of October, and full operational readiness is aimed for by the end of the year. The scientists are convinced that the expanded capacities will enable the institute to stay at the forefront of microdisplay technologies and offer a unique portfolio, from design to manufacturing to pilot production.

www.ipms.fraunhofer.com

The Fraunhofer IPMS is considered the only independent research and development center worldwide for microdisplay technologies, which also integrates backplane IC design in silicon foundry processes and OLED-on-silicon manufacturing technology under one roof. This allows the institute to develop and manufacture customer- and application-specific OLED microdisplays. However, scientists are also developing backplanes for other display technologies, such as micro-LED and LCOS (liquid crystal on silicon).

To continue being a leading provider of technology developments, the institute has now expanded and renewed its plant technology. This innovative technology promises a significant improvement in the efficiency and quality of manufacturing high-resolution microdisplays.

The new tools enable the thermal deposition of complex organic stacks, metal layers, and oxides, facilitating the development and manufacture of high-resolution OLED microdisplays as well as sensors such as organic photodiodes.

“With the new equipment, we can thermally deposit complex organic stacks, metal layers, and oxides that enable us to develop and manufacture ultra-high-resolution OLED microdisplays, as well as sensors such as organic photodiodes,” explains Bernd Richter, head of microdisplay and sensor technology at Fraunhofer IPMS. “The industry-compatible systems are state-of-the-art and can be flexibly combined to meet the high demands of research and development projects while also providing high efficiency for pilot production.”

Specifically, the new technology achieves higher throughput, and significantly improved process control leads to stable manufacturing processes. The new etching chamber of the system can perform various pretreatments of wafers from different suppliers.

The greatest challenge in this context was to couple the new vacuum system components with the existing plant technology.

The scientists are confident that they can remain competitive and offer their customers a unique portfolio: from the design of microdisplays to the production of initial prototypes to pilot manufacturing from a single source.

The acceptance of the new system is planned for the end of October, and full operational readiness is aimed for by the end of the year. The scientists are convinced that the expanded capacities will enable the institute to stay at the forefront of microdisplay technologies and offer a unique portfolio, from design to manufacturing to pilot production.

www.ipms.fraunhofer.com