electronics-journal.com

29

'25

Written on Modified on

Critical Manufacturing Showcases AI-Driven Factory of the Future Experience

The Manufacturing Operations Platform integrates MES, IoT, automation, analytics, and AI to connect machines, data, and people—enabling real-time insights, predictive quality, and intelligent decision-making.

www.crossmanufacturing.com

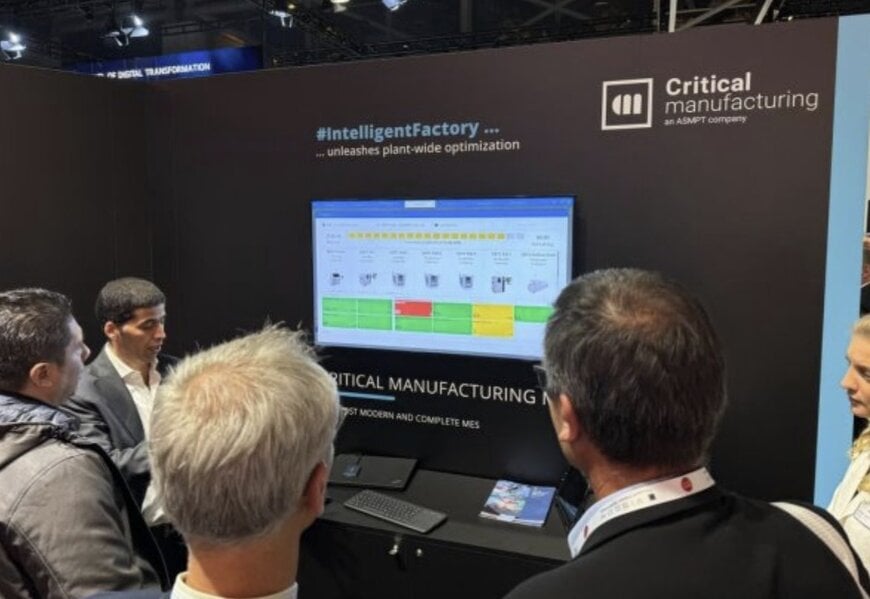

At SEMICON Europa and productronica (November 18–21), in collaboration with ASMPT, Critical Manufacturing will show how the factory of the future operates as one connected system where people and AI collaborate seamlessly. The company's Manufacturing Operations Platform unites MES, connectivity, automation, analytics and AI to help manufacturers master complexity, accelerate decisions, and gain the trust and speed they need to compete.

Visitors will see a live demonstration of the Factory of the Future in action. Data from a reflow oven will be connected, contextualized, and analyzed to show how information flows seamlessly across machines, materials, and quality systems. By identifying correlations between process parameters and defect patterns, the system enables the prediction and prevention of quality issues. Users can interact with the data through an AI copilot, asking natural-language questions to reveal insights directly from production data. This demonstrates how manufacturers can move from digital transformation to intelligence transformation, where AI and automation turn insights into real-time decisions that optimize performance and prevent issues before they occur.

"Electronics and Semiconductor manufacturing demands speed, precision, and the ability to learn at every stage of production," said Pedro Oliveira, Industrial Solutions Engineer for Electronics/SMT at Critical Manufacturing. "We know today that AI is only as strong as the data behind it. At productronica, our visitors can explore how by connecting machines, MES, and the IoT Data Platform, we are helping our customers build the factory of the future, one where AI continuously learns from data to drive better outcomes."

For the Semiconductor demonstration, visitors will see how the Manufacturing Operations Platform ensures complete materials traceability, in line with E142 standards, uniting MES, IoT, and AI to deliver contextualized, real-time insights. These capabilities give chipmakers the agility and confidence to optimize throughput, prevent variability, and sustain yield, especially in complex, data-rich environments.

Complementing these capabilities is c-Alice, the company's AI-powered image classification tool, which improves process control through the analysis and classification of images acquired in production.

"Manufacturers across semiconductors and electronics face unprecedented complexity but also enormous opportunity," said Tom Bednarz, Managing Director for Germany at Critical Manufacturing. "We will show how our platform transforms that complexity into a strategic advantage and enables continuous innovation in industries that are evolving faster than ever."

Visitors are invited to meet Critical Manufacturing experts at the Smart Manufacturing Pavilion, Booth B1734 (SEMICON Europa) or at the ASMPT Booth, A3.377 (productronica) to explore how the company's Manufacturing Operations Platform can future-proof their operations.

www.criticalmanufacturing.com