electronics-journal.com

06

'26

Written on Modified on

Contrinex Expands Digital Distance Sensors for Flexible Automation

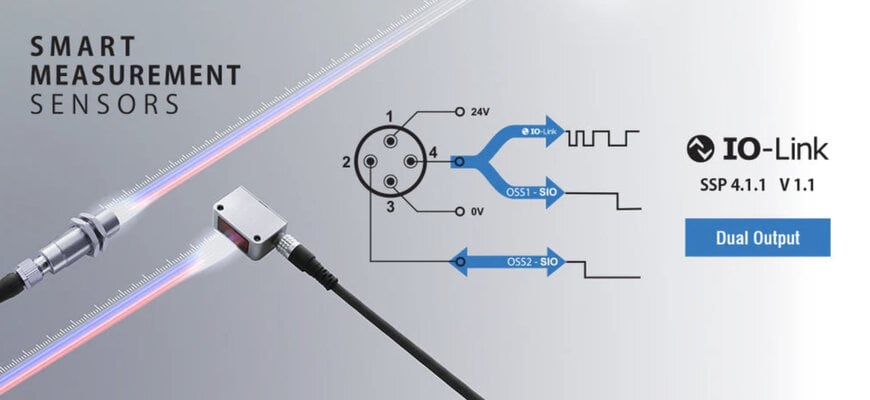

Smart digital measurement sensors from Contrinex combine high-resolution distance sensing with configurable outputs and diagnostics to support modular automation, IIoT integration, and predictive maintenance strategies.

www.us.contrinex.com

As industrial automation systems become more modular and data-driven, distance sensors are increasingly expected to do more than deliver raw position values. Engineers now require measurement devices that combine accuracy with flexible configuration, diagnostic visibility, and straightforward integration into modern control architectures. Smart digital measurement sensors are designed to address these requirements by extending conventional distance sensing into a configurable, system-aware function.

At the measurement level, these sensors provide continuous, linear distance data with high resolution, allowing precise detection of position changes across the defined sensing range. Linear digital signal representation ensures that distance information can be processed reliably by PLCs, motion controllers, or higher-level automation systems, supporting applications such as position feedback, dimensional verification, and process monitoring.

Beyond measurement accuracy, configurability plays a central role in adapting a single sensor platform to multiple applications. Smart digital measurement sensors typically incorporate two independently configurable outputs, enabling users to assign analog or digital behavior depending on system requirements. One output can be configured as a switching signal, an additional input, or a wire-teach interface, reducing the need for external components and simplifying commissioning during both new installations and retrofits.

Advanced configuration functions extend sensor operation beyond basic threshold detection. Adjustable timing functions such as delay, stretch, and one-shot control allow precise signal conditioning within the sensor itself. Event-based alarms, counters, and integrated temperature monitoring provide additional context for process behavior, while onboard data storage preserves configuration parameters and operational information during power cycles or maintenance activities.

These capabilities support the transition toward smarter automation and Industrial Internet of Things (IIoT) architectures. By generating condition-based and event-driven diagnostic data directly at the sensing point, smart digital measurement sensors enable early detection of deviations and support predictive maintenance strategies aimed at reducing unplanned downtime.

Mechanical design also remains critical in industrial environments. Variants with stainless steel V2A housings and high-pressure resistance allow deployment in corrosive, mechanically demanding, or hygienic applications without compromising sensing performance or service life.

By integrating precise distance measurement with configurable outputs, embedded diagnostics, and robust construction, smart digital measurement sensors provide a flexible sensing foundation for modern automation systems that demand both accuracy and adaptability.

www.contrinex.com