Nanoscale sensors enable pervasive temperature and force sensing

Digid qualifies printed electronics technology for volume production of micrometre-scale sensors targeting robotics, medical devices, and advanced biosensing applications.

www.digid.com

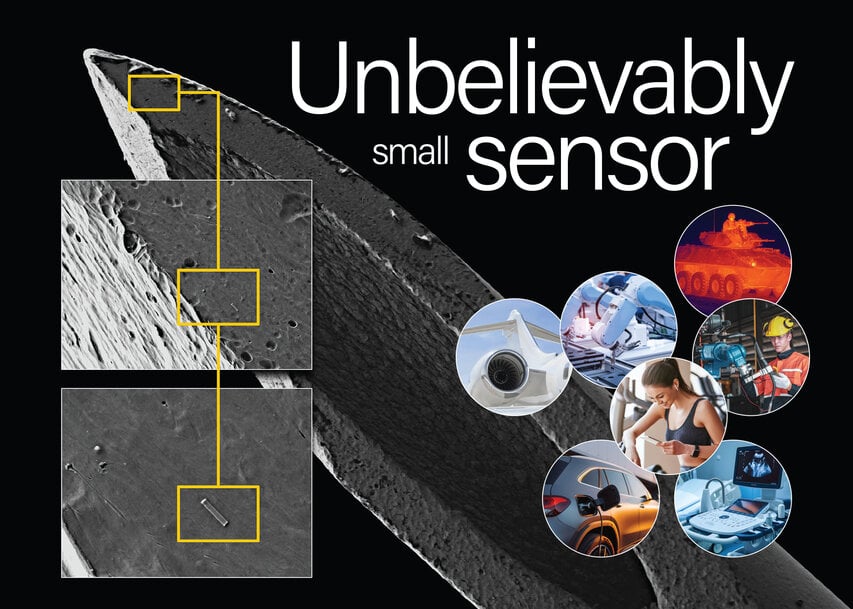

Digid has announced that its patented printed electronics fabrication process is now qualified for mass deployment of nanoscale temperature and force sensors. The technology enables sensors as small as 1 µm in length to be deposited directly onto a wide range of substrates, including silicon, metals, polymers, and composite materials, supporting high-volume manufacturing for emerging sensing-intensive applications.

Nanoscale sensing platform and roadmap

The current production-ready sensors measure approximately 1 µm, positioning them among the smallest temperature and force sensors available for industrial use. According to Digid’s technology roadmap, the same fabrication approach is expected to scale further, with future generations targeting sensor dimensions down to approximately 10 nm.

The sensors are produced using a printed electronics process, allowing direct deposition onto functional surfaces rather than requiring discrete sensor packaging. This approach supports high spatial resolution sensing and enables dense sensor placement in locations where conventional sensors cannot be integrated.

Addressing limitations in robotics and physical AI

One of the primary application drivers for the technology is robotics, particularly humanoid and physical AI systems. Robotic manipulation remains constrained by limited tactile and thermal feedback, a challenge often described in the context of Moravec’s paradox. Digid’s sensors can be arranged in surface-mounted arrays, for example up to 16 × 16 elements, enabling distributed force and temperature sensing across robotic shells, grippers, or contact surfaces.

By increasing sensing density and proximity to points of contact, the technology supports more precise interaction with fragile or irregular objects, improving feedback for control algorithms without significantly increasing system size or power consumption.

Medical, energy, and biosensing applications

Beyond robotics, Digid’s sensors are designed for integration into medical and energy systems where minimal size and low thermal impact are critical. Example use cases include force sensing on robotic surgical tools, temperature measurement at the tip of minimally invasive probes, and temperature monitoring embedded within battery cells to support safety and performance management.

The platform is also applicable to biosensing, where nanoscale sensors can be used to detect biological entities such as viruses or chemical markers associated with pharmaceuticals in the bloodstream, enabling localized and minimally invasive measurement approaches.

Integration and signal processing

Digid provides a complete integration solution for customer projects, supplying custom sensor designs along with hardware and software support. The sensors output either voltage or resistance measurements via an I²C interface. Dedicated signal processing software converts raw sensor data into calibrated temperature or force values suitable for system-level use.

Due to their nanoscale dimensions and printed structure, the sensors exhibit negligible self-heating and minimal measurement distortion. The linear response characteristics reduce the need for drift compensation or complex calibration routines, lowering digital processing overhead compared with conventional sensing technologies.

Availability and deployment readiness

With volume production now qualified, Digid’s nanoscale temperature and force sensors are positioned for deployment in high-density sensing applications across robotics, medical technology, energy systems, and biosensing. The combination of ultra-small form factor, substrate flexibility, and simplified integration supports new sensing architectures where distributed measurement was previously impractical.

www.digid.com