electronics-journal.com

19

'21

Written on Modified on

ROHM Completes Construction of a New Environmentally Friendly Building at its Apollo Chikugo to Expand Production Capacity of SiC Power Devices

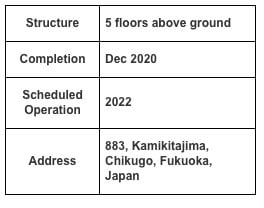

ROHM has recently held an opening ceremony announcing the completion of a new building at ROHM Apollo's Chikugo plant started in February 2019 to enhance the production capacity of SiC power devices.

In addition, we have strengthened our BCM (Business Continuity Management) system by introducing various disaster countermeasures. And from January 2021, we will begin installing production equipment and build a manufacturing system that can meet the medium- to long-term increases in demand for SiC power devices.

ROHM, which has been mass producing SiC power devices including SiC SBDs and MOSFETs since 2010, continues to lead the industry in technological development, such as by introducing the industry's first full SiC power modules and SiC trench MOSFETs. At the same time, boasting an integrated production system, ROHM is working to improve production efficiency by increasing wafer diameter and utilizing the latest equipment while also reducing the environmental impact of manufacturing.

In addition to this new building, SiCrystal GmbH, a ROHM Group company that manufactures SiC wafers, is scheduled to start operating with 100% renewable energy from the next fiscal year, reducing CO2 emissions from purchased power at the plant to zero. As a result, all major production processes for SiC wafers will use environmentally friendly renewable energy.

In response to the urgent need to address global energy issues, the ROHM Group will continue to improve SiC power device performance – expected to be key to achieving energy saving in electric vehicles and industrial equipment – contributing to reducing environmental impact by promoting the use of eco-friendly equipment and renewable energy in the production process.

Seismically Isolated Structures Adopted (Including Ancillary Areas)

Overview of the New ROHM Apollo Building

The new building is designed to save energy by introducing measures such as a high-efficiency air conditioning system that makes effective use of exhaust heat, a pure water production system, and LED lighting, reducing CO2 emissions by 20% (approx. 7,000 tons) over conventional facilities.

Gas Fire Extinguishing System Safe for People and Equipment

And in addition to adopting seismically isolated structures (including ancillary areas) against earthquakes, we have introduced flood countermeasures, gas fire extinguishing equipment, and emergency generators to prepare for a variety of disasters.

Emergency Generator

The ROHM Group’s Environmental Approach to Manufacturing

The ROHM Group pursues recycling-oriented management by minimizing the impact on the global environment (i.e. chemical substances, waste) through factories that comply with the ISO 14001 standard for environmental management systems.

In addition, to prevent global warming and decrease greenhouse gas emissions, we are establishing mechanisms and production technologies that reduce environmental impact, such as implementing smart factories and the use of renewable energy.

At the ROHM Apollo Chikugo plant, we introduced renewable energy in FT 2019 and have gradually increased the amount of electricity generated. The ROHM Group is committed to continuing to work to reduce the environmental burden of manufacturing while contributing to a decarbonized society by supplying products that minimize environmental impact utilizing renewable energy and other resources.

www.rohm.com