electronics-journal.com

28

'21

Written on Modified on

Ultra-compact and highly responsive PTC thermistor solution for space-limited designs

Murata has expanded its portfolio of positive temperature coefficient (PTC) surface-mount chip thermistors for overheat sensing by introducing the PRF03BB541NB7RL.

These thermistors are optimised for incorporation into various forms of consumer electronic products and equipment such as wearable technology, smartphone handsets and tablets.

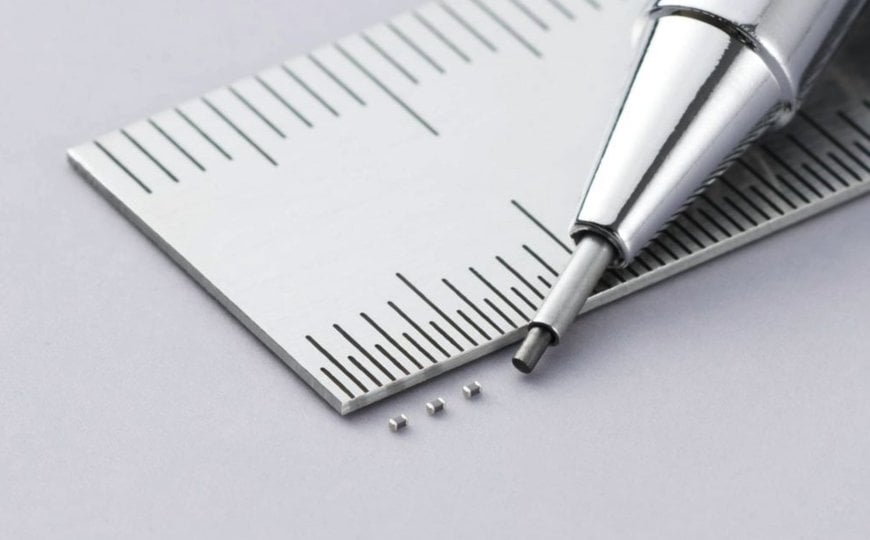

Supplied in a 0201 format (with 0.6mm × 0.3mm × 0.3mm dimensions), they present engineers with the smallest overheat sensing solution currently available on the market. The thermistors offer elevated levels of accuracy (±5°C at lower sensing temperatures, and up to ±7°C at higher sensing temperatures) as well as rapid responsiveness. Their resistance values increase sharply once above the Curie temperature. This means that overheat situations can be addressed quickly, thereby reducing the risk of damage to circuitry.

The new thermistors directly benefit from Murata’s proprietary ceramic technology, with innovations being realised in relation to both the raw material composition and sintering procedure too. The result is that a significant downsizing can be achieved without any compromise in performance. Furthermore, the thermistors have strong operational stability and do not generate any noise which would otherwise affect neighbouring components.

The PRF03BB541NB7RL exhibits industry-leading robustness. It has a maximum voltage rating of 32VDC and supports an extensive working temperature range of -20°C to +150°C.

“The increasing density of components in modern electronic designs makes dissipation of heat an ever greater challenge,” states Takahiro Takagi, General Manager, Product Engineering Department, Functional Device Division at Murata. “By using thermistors that take up less board footprint, it is possible to improve overheat sensing accuracy as they can be placed closer to the areas that need to be monitored. Specifying these components also enables a reduction in the overall bill-of-materials costs.”

Samples are available now with mass production set to begin in June 2021.

www.murata.com