electronics-journal.com

15

'21

Written on Modified on

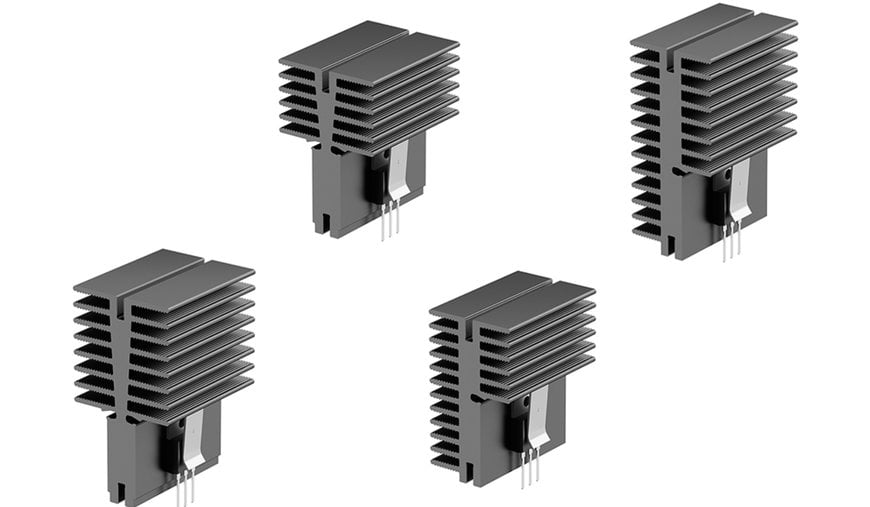

INNOVATIVE EXTRUDED HEAT SINKS FOR LOCK-IN TRANSISTOR RETAINING SPRINGS

So-called circuit board heatsinks for lock-in transistor retaining springs are very often used for greater power losses of electronic components that are installed on a printed circuit board.

The thermal performance data of today’s devices on the circuit board require efficient heatsink solutions, which is why Fischer Elektronik GmbH & Co. KG is expanding its existing product range to include additional functional geometries. The product types SK 662, SK 664, 665, SK 669 and SK 681 provide efficient solutions in different sizes and lengths for device cooling. Mounting the heatsinks to the circuit board can work in a number of ways. The circuit board heatsinks have an extruded thread channel in the base of the heatsink, which is placed on the circuit board. A metric M3 screw can be screwed into this from the back of the circuit board for fastening with the same. It is also possible to press a brass bolt (item no. ELS 3) with a solderable surface coating into the threaded channel so that it cannot be lost when soldering. The circuit board heatsink can thus be handled like an electronic device and, for example, connected or soldered to the circuit board using the reflow soldering process. On the top of the respective circuit board heatsink there is also an integrated threaded channel in the profile, which can also be used as a fastening element in a wide variety of applications.

The mounting of the respective transistors installed on the circuit board to the circuit board heatsink is often viewed by the customer as a cost reduction factor. The simplification of transistor assembly is ensured with the various types of printed circuit board heatsinks for lock-in transistor retaining springs by means of a special groove geometry being integrated in the heatsink. This is inserted directly during the extrusion of the profile and gives the user the decisive advantage that the transistors to be fastened can be locked directly into the groove using specially shaped locking transistor retaining springs made of stainless steel (item no. THFU) using the clip function. The thus achieved simple assembly with a secure hold causes an optimal heat transfer between the device and the heatsink mounting surface. Once snapped in, the spring holds it immovably in its position and fixes the transistor on the mounting surface with high pressure. The lock-in transistor retaining spring cannot be displaced in its position in the longitudinal direction, and it is not possible to fall out in the transverse direction.

In addition to the extensive product range of circuit board heatsinks for lock-in transistor retaining springs, Fischer Elektronik offers additional mechanical processing as well as customer-specific solutions and heatsink geometries.

The listed innovations from the product area of circuit board heatsinks for lock-in transistor retaining springs as well as all innovations from Fischer Elektronik can also be found in our shop.

www.fischerelektronik.de