electronics-journal.com

20

'21

Written on Modified on

AI entry made easy

AI (Artificial Intelligence) can be used to automate many processes related to quality assurance and predictive maintenance.

The challenge lies not only in capturing the expertise of employees for algorithms. Above all, there are hardly any electronics in practice that meet the requirements of industry. Embedded manufacturer Kontron has now developed a robust AI platform that simplifies the entry into Google's TensorFlow world in the factory.

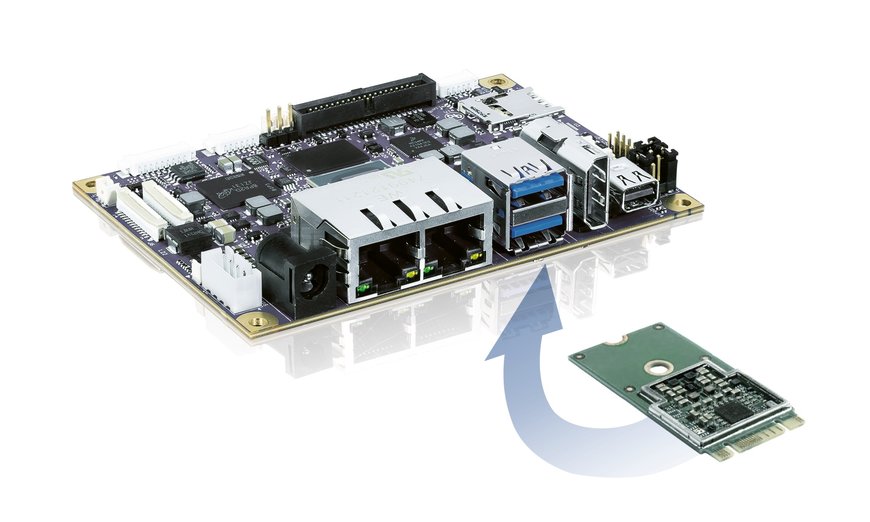

Engineers and developers in the production environment often face considerable challenges when entering AI topics around Deep Learning based on neural networks. Here in particular, the edge electronics must function robustly and be easy to use on site. Kontron has therefore developed a platform that significantly simplifies AI use. The compact AI device platform consists of an M.2 module with the Google Coral accelerator chip for the TensorFlow Lite software ecosystem on a 2.5" pITX single board computer with the NXP i.MX8M processor. A box PC product based on the Google Coral M.2 module integrated into an Intel Atom® processor platform is expected to be available before the end of the first quarter of 2021. Industrial suitability and robustness were at the top of the development agenda. Thus, the NXP-based AI platform can be used for operation in a high temperature range of -40 to +85 degrees. It is also designed for high mechanical resilience and contributes to sustainability as a low-loss solution.

Overcoming obstacles on the shop floor

AI tasks involving image processing require camera systems. As a rule, corresponding USB cameras have a limited cable length, so the computer platform must be located in close proximity. In the future, the cameras could also be connected with Power over Ethernet (PoE) to bridge greater distances - and without the need for a separate power cable. The Dedicated Tensor Processing Acceleration Unit (TPU) enables small and low power applications from 2 TOPS per watt up to 4 TOPS (trillion operations per second). Especially in high ambient temperatures of over 50 degrees Celsius - such as in the inspection of metal castings - low power consumption is essential: here, devices should have the lowest possible temperature development in order to be able to withstand a high temperature range. Not only for safety reasons, but also because of the high performance requirements, AI functionality in the production environment is usually relocated to edge components on site instead of mapping the data collection and processing via the cloud. With the AI platform, customised systems can be developed to meet these requirements.

Automating visual inspection

One of the most important areas of application for AI algorithms at present is in the field of quality assurance, where a whole range of tasks can be automated that were previously done by experienced professionals. This includes, for example, the visual inspection of surfaces or checking whether all components of a product are correctly assembled. Algorithms learn on the basis of image data that are labelled accordingly. In the environment of Smart Factory and Predictive Maintenance, Deep Learning also supports image recognition to detect problems at an early stage. Corresponding application scenarios exist, for example, in the automotive industry, where comparatively inexpensive wear parts such as robot welding tongs are monitored. By detecting wear in good time, expensive line stoppages can be avoided. However, such solutions depend on high performance image recognition. Here, it is important to process as many images (frames) per second as possible. Although camera systems generate an average of around 400 frames per second, conventional processors only process a fraction of the images. Kontron's AI platform therefore uses the Google Coral Edge TPU accelerator card to ensure higher processing levels.

Significantly higher performance in image processing

As a gateway platform, the NXP i.MX8M-based solution offers several USB interfaces and powerful ports to connect cameras for visual inspection, for example. The single board with integrated accelerator card is a cost-effective approach in a small form factor for setting up gateways. The speed of image processing plays a particularly important role where quality has to be assessed in real time on the production line. Around ten images have to be examined in order to detect defects on an object while it is being transported on the assembly line. Depending on the camera system, the AI solution can process up to 100 frames per second. This makes it possible to achieve considerable leaps in speed, whereas less powerful systems would slow down production processes. For about ten per cent extra cost of the CPU board, about ten times the performance can be achieved.

The AI platform also uses a Linux Yocto kernel as a guarantee for up-to-date security features. This means that individual requirements can be addressed in even greater detail in the application. The platforms can be integrated into systems such as box PCs, HMIs or rack servers. This is also a good way to address a trend that will continue on a massive scale in 2021: In practice, the software share in companies' projects continues to increase in many areas. Kontron has positioned itself accordingly and also meets its customers needs with AI software, hybrid cloud and big data. This is important, because a lot of potential for process optimisation can only be leveraged if hardware and software interact perfectly. This is not possible without a sound understanding of processes.

Good for innovation

In the AI environment, everything depends on the data and, above all, high data volumes on which algorithms are trained. The preliminary work for more complex projects includes collecting as many thousands of images as possible, which have to be labelled accordingly. On this basis, the algorithm learns to evaluate how good or bad the quality of an object is, for example. Particularly in small and medium-sized enterprises, another hurdle for manufacturing companies is the lack of expertise in data science. This is often due to the lack of skilled workers. Kontron Data Scientists therefore advise on implementation and realisation: within the framework of projects, employees are trained and strategies for integration into other production lines are developed. Kontron AIS, as a specialist for industrial automation solutions with more than 30 years of experience, also offers support.

A key advantage of the Kontron AI platform is the access to all TensorFlow Lite applications, which can be downloaded directly into the platform. Experience shows that first successes can be achieved comparatively quickly on the basis of existing algorithms. Thus, own applications can be developed in a short time with neural networks and Deep Learning around object recognition and classification of objects: The pre-trained neural networks can be used as a basis for this and contribute to a shortened time-to-market.

www.kontron.com

Author: Reiner Grübmeyer, Director Product Management Systems & Software at Kontron.