Murata introduces a resin-molded thermistor with wire-bonding

Murata Manufacturing launched the FTI Series NTC thermistor, the first to achieve resin-molded design and wire-bonding compatibility, catering to automotive thermal management needs.

www.murata.com

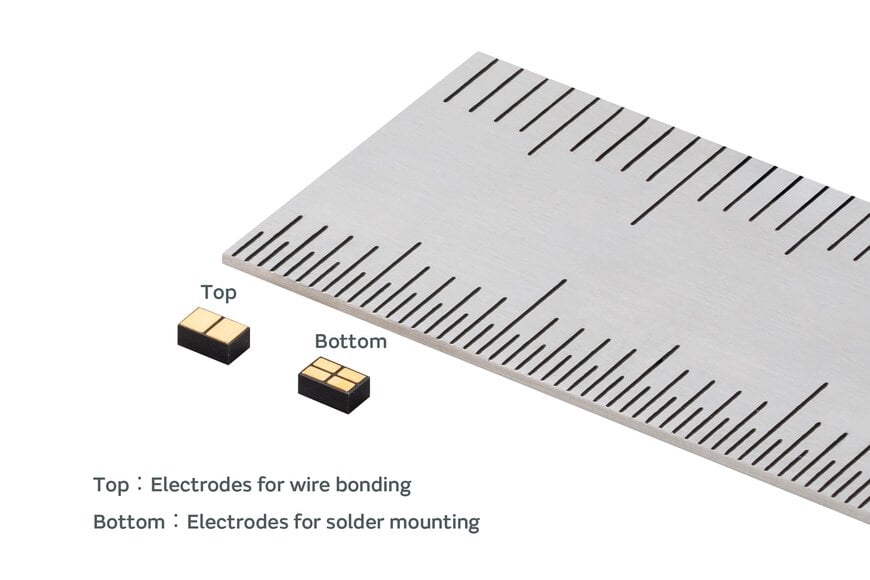

Murata Manufacturing has announced the launch of the FTI Series (FTN21XH502F0SRU), a groundbreaking NTC thermistor that sets a new industry standard for automotive thermal management. The product is the world’s first to achieve both a resin-molded design and wire-bonding compatibility in a single thermistor. The integration of these two innovations provides unprecedented flexibility for designing and assembling printed circuit boards (PCBs), directly addressing the needs of modern automotive applications, including electric vehicle (EV) inverters and DC-DC converters.

Featuring a resin-molded structure, together with wire-bonding compatibility, allows for highly flexible installation directly on the PCB and in closer proximity to power semiconductor components. This advancement eliminates the need for dedicated sensor mounting pads, which have traditionally restricted layout options and increased board size. As a result, design engineers gain much greater freedom in PCB design, enabling more compact and efficient modules – especially important in modern EVs, where electronic controls must be highly integrated in tight spaces.

Another key strength of the FTI Series is its high-temperature operating capability. Leveraging Murata’s proprietary external electrode bonding technology, the thermistor ensures reliable performance in harsh environments, with guaranteed operation up to 175°C. This is among the highest in the industry and is critical for next-generation automotive applications, especially within powertrains and other high-power modules where heat management is a constant challenge. With this level of heat resistance, automotive designers can ensure the safety, stability, and longevity of their systems even under demanding conditions, such as those found in EV inverters and DC-DC converters.

By enabling precise and rapid temperature measurement directly adjacent to semiconductor devices, the FTI Series allows for a reduction in temperature margins within a system’s design. This means that a power semiconductor’s performance can be maximized without over-engineering for excessive safety margins, creating opportunities to reduce the size of chips or the number of chips used in parallel, leading to smaller modules and lower overall costs. Further, this cost-saving feature does not come at the expense of reliability or performance, making the thermistor an ideal solution for manufacturers seeking to optimize their designs both technically and economically. The FTI Series is available in a compact 2012 mm / 0805-inch package and exhibits a resistance at 25 °C (R25) of 5 kΩ ± 1% with a B-constant (25 °C / 50 °C) of 3380 K ± 1%.

“In response to the increasingly sophisticated requirements of the automotive market, Murata remains committed to expanding its product lineup to include a broader range of resistance values and to offer new variations, such as silver sintering-compatible models in addition to traditional solder-mounted types,” said Munenori Hikita, Director of Functional Devices Division at Murata. He continued, “Through these ongoing efforts, and development of solutions like the new FTI series, Murata continues to support the advancement of EV technology and the broader automotive industry by delivering innovative, reliable, and cost-effective solutions.”

www.murata.com