electronics-journal.com

04

'20

Written on Modified on

MAJOR ORDER FROM CHINESE ORIGINAL EQUIPMENT MANUFACTURER: INTEGRATED LIGHTING SYSTEM SOLUTION FROM HELLA

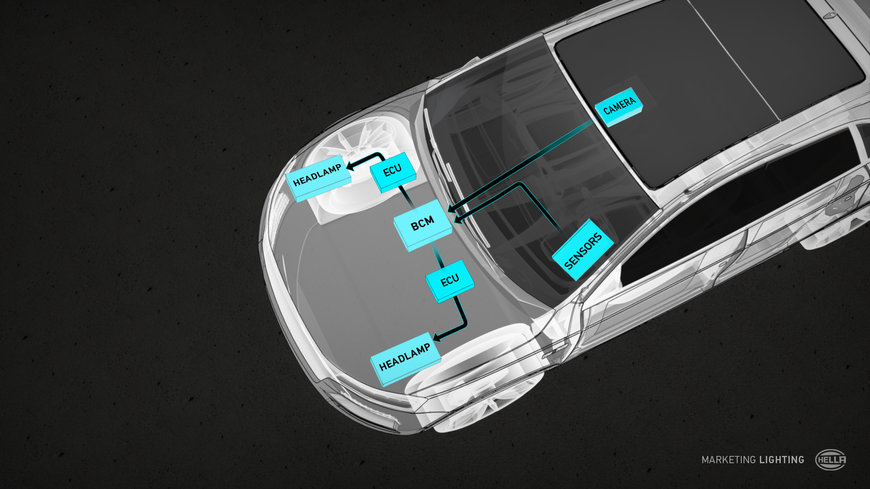

The "Light Design" package includes all components for complex lighting systems: matrix LED headlamps, light control electronics and sensor technology.

The lighting and electronics specialist HELLA has been commissioned by a leading Chinese electric vehicle manufacturer to produce integrated lighting systems. The customer project includes two vehicle series: the first has recently been launched, the second is planned for the end of the year. The system solution is based on the modular principle "Light Design" developed by HELLA, consisting of matrix LED headlamps, light control electronics and the necessary sensor technology. A software tool designed by HELLA was also used in the development process. It allows front lighting functions to be digitally simulated and individually adapted.

"Intelligent lighting functions, such as glare-free high beam, which is already used extensively in the premium segment, are also becoming more and more common in the volume segment. As a result, automotive lighting technology is becoming increasingly more sophisticated, because numerous lighting and electronic components have to be integrated and coordinated with each other", says Dr. Frank Huber, member of the HELLA Management Board and responsible for the global lighting business.

"As lighting and electronics experts, we can benefit from our comprehensive complete system competence in this area. When choosing us, the entire process chain comes from a single source, from headlamps to electronic control units and software. This allows us to make it much easier for our customers to integrate the product and to offer a system that is optimally adapted to their needs."

HELLA was the first to introduce the "Light Design" approach to the market in the middle of last year. Here, all lighting and electronic components for complex lighting systems can be combined using a modular principle and integrated by HELLA into a complete system. The first customer project involves a matrix headlamp with 24 individually controllable LEDs, which is produced in the plant of the Chinese lighting joint venture Hella BHAP Sanhe Automotive Lighting, and lighting electronics and level sensors, which roll off the production line in the electronics plant in Shanghai. Furthermore, a front camera, including the relevant image processing software, is integrated into the complete system.

The lighting and electronics divisions of HELLA collaborated closely to develop the complex system solution within about one and a half years.

www.hella.com